Ever wondered what’s happening behind the scenes in computer vision? Is it really as simple (or complex) as it seems?

Well, in this video we’re diving into the incredible technology that powers Kibsi’s no-code computer vision platform. Of course, Kibsi supports dozens of industries and an unlimited supply of use cases, but in this example, we’re going to look at a scenario that’s deceptively simple – packing a box!

Recently, Julie had an eye-opening conversation with Carter Brown, one of our Kibsi CV Engineers and all-around genius, about this particular use case. He shared some insights into the tech decisions happening behind the scenes that were so interesting Julie demanded that she be allowed to record it to share with other Kibsi fans and computer vision aficionados.

The video you’re about to see may not seem thrilling (it’s just someone packing a box after all), but the magic is in how we monitor the packing process. We’re keeping track of items, checking for overlaps, and connecting that data to an inventory system – all without the person having to scan each item. It’s a seamless integration of computer vision and daily operations.

As Carter explains, in this demo we see someone packing a box with various items. It may look simple, but there’s a lot happening behind the scenes.

First, in order to successfully deliver on this use case, our Kibsi vision platform had to be capable of operating at any frame rate. In this example, the person packs items quickly, so we’re running at 30 FPS (frames per second). Other use cases might not need that kind of speed (in fact, most security camera footage is captured at just 10 FPS).

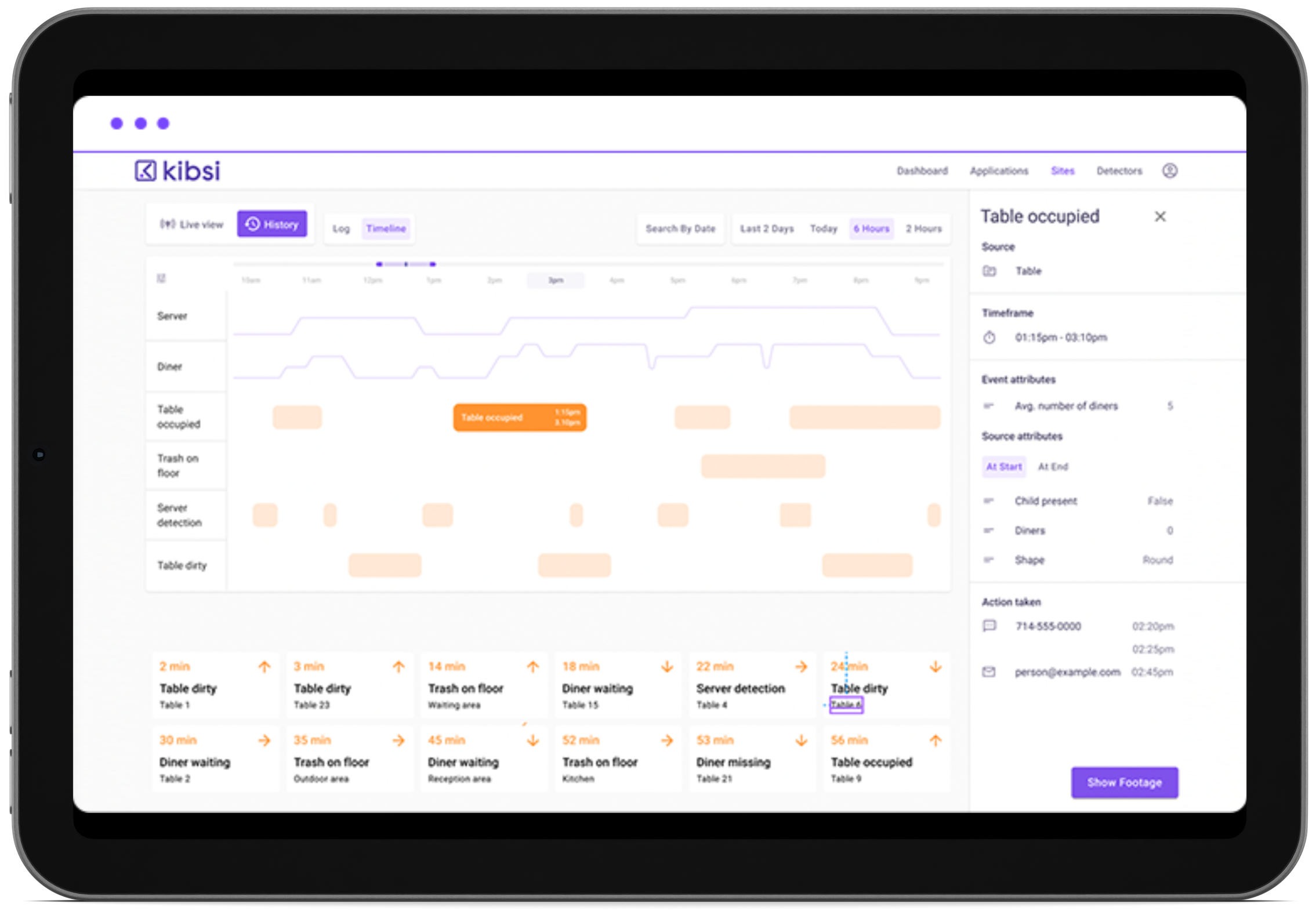

To monitor the packing process, we use Kibsi’s no-code platform to define regions within the video frame. In this case, we have a region around the box where items are placed. As the person adds new products to the box, a green bounding box appears around the item, showing that it has entered the designated region.

Now, it might seem challenging for the model to track items stacked on top of each other but not for Kibsi! Our platform knows and remembers that an item is “in the box” once it has entered the region and this works the other way, too, if it’s taken out. This same technical approach continues to be vital as the packing continues and items become denser within the box. By effectively keeping track of items entering or leaving the region, Kibsi can keep count even if they are partially or entirely obscured.

In addition to monitoring the packing process, we use Kibsi’s events feature to support inventory management. When an item enters the box, it triggers an event, which can send a webhook to a secondary app. This app can then update the inventory in real time, ensuring that the system remains up-to-date and accurate.

In the demo, you’ll see the inventory counter drop and the box counter increase as items are added. If the person packing the box adds an extra item by mistake, the system flags it as an error. The person can then remove the item, and the inventory and box counters are updated accordingly.

This video is just one example of how the combination of Kibsi’s video intelligence, computer vision, and event-triggered updates allows businesses to manage inventory more effectively and streamline their operations. And all of this is made possible with just a few of the out-of-the-box features that Kibsi has to offer – pun intended!

So, there you have it! We hope you enjoy this behind-the-scenes look at the power of Kibsi’s video intelligence and computer vision technology. Stay tuned for more exciting insights and use cases from the world of computer vision.