Introduction

In the intricate world of logistics, distribution, or manufacturing, the goods receiving process is a pivotal junction. For operations leaders, this process is akin to a ballet, where precision, timing, and accuracy are paramount. Every box that arrives at the receiving dock carries with it the promise of meeting customer demands, replenishing stocks, or fueling production lines. However, the traditional way of handling this step is fraught with challenges. It’s tedious, prone to human errors, and is often a bottleneck in the supply chain. But imagine for a moment, a world where the process is not only streamlined but also becomes a source of strategic advantage. Welcome to the future of goods receiving — powered by video intelligence.

The Traditional Goods Receiving Process: A Challenge Ripe for Innovation

Every day, thousands of boxes make their way into warehouses and distribution centers around the world. Upon arrival, each box undergoes a manual examination, turning the receiving dock into a beehive of activity.

Issues with the Traditional Process:

- Time-Consuming: Every box is a universe in itself, brimming with information. From the SKU, which determines the specific stock type, to barcodes that offer product details, to shipping labels that hint at the product’s journey – each needs thorough inspection. This isn’t just about matching goods to a list; it’s about ensuring that every product received is ready to contribute positively to the operational flow. And this meticulous process, when done manually, consumes precious hours.

- Error-Prone: The more the data points, the higher the chances of errors. With multiple labels on a single box, the possibility of missing crucial details or misinterpreting them is high. For instance, a single misread barcode could result in mis-stocked goods, leading to larger inventory discrepancies down the line.

- Labor Intensity: This isn’t just about the time it takes but the sheer manpower required. Warehouses often have teams dedicated solely to receiving and verifying goods. These are individuals whose skills could be better utilized elsewhere, but they remain tied to this repetitive and routine task.

Video Intelligence: The Future of Goods Verification

The above challenges paint a cumbersome picture. But what if we told you that the future promises not just efficiency but also accuracy, speed, and optimal resource utilization? Enter the world of Video Intelligence.

How it Works:

- Seamless Scanning: As boxes whizz by on conveyor belts, state-of-the-art cameras, positioned strategically, capture images of every facet of the box. Whether it’s the side with the barcode or the one with shipping details, no data goes unnoticed.

- Data Extraction via Advanced Algorithms: Beyond just capturing images, the real magic lies in deciphering them. Advanced algorithms, perfected over time, analyze these images. They’re trained to detect, interpret, and extract data from every conceivable label and code present on the box.

- Instantaneous Comparison: Once extracted, this data isn’t just stored — it’s immediately put to work. By integrating with your purchasing system and inventory databases, the system verifies the authenticity and accuracy of the received goods in real-time.

- Proactive Alerting System: In the rare event of a discrepancy, the system doesn’t wait. It proactively generates real-time alerts, ensuring that anomalies are caught early and corrective actions can be initiated promptly.

In a world that’s rapidly moving towards automation and efficiency, the fusion of video intelligence with goods verification isn’t just a fancy tech upgrade. It’s a strategic move that promises tangible operational benefits and sets forward-thinking organizations miles ahead of the curve.

Case in Point: A Success Story (Name withheld due to NDA)

In a bustling warehouse, where every second counts, our collaboration with a top-tier company stands as a testament to the transformative power of video intelligence in goods verification. This company, renowned in its sector, faced the same challenges that many in the logistics and manufacturing industries grapple with: time-intensive manual verifications and the associated human errors.

Our solution? We are integrating our state-of-the-art video intelligence technology into their existing systems. The outcome is beyond impressive.

- Manpower Reallocation: The most tangible result is the expected savings of an estimated 9,000 worker hours. These hours aren’t just ‘saved’; they are reallocated. Freed from the manual drudgery of box-checking, their skilled workforce can shift focus. They can now address the rare discrepancies that arise, ensuring that exceptions are handled with expert precision.

- Skill Optimization: With automation shouldering the bulk of the verification process, employees will now be deployed to tasks that demand human intellect and expertise. This has led to enhanced skill utilization and job enrichment, resulting in a motivated workforce and improved workflow dynamics.

Why Kibsi is the Game-Changer in Goods Verification

In the evolving landscape of logistics and warehousing, Kibsi emerges as a beacon of innovation, driving operations into the future.

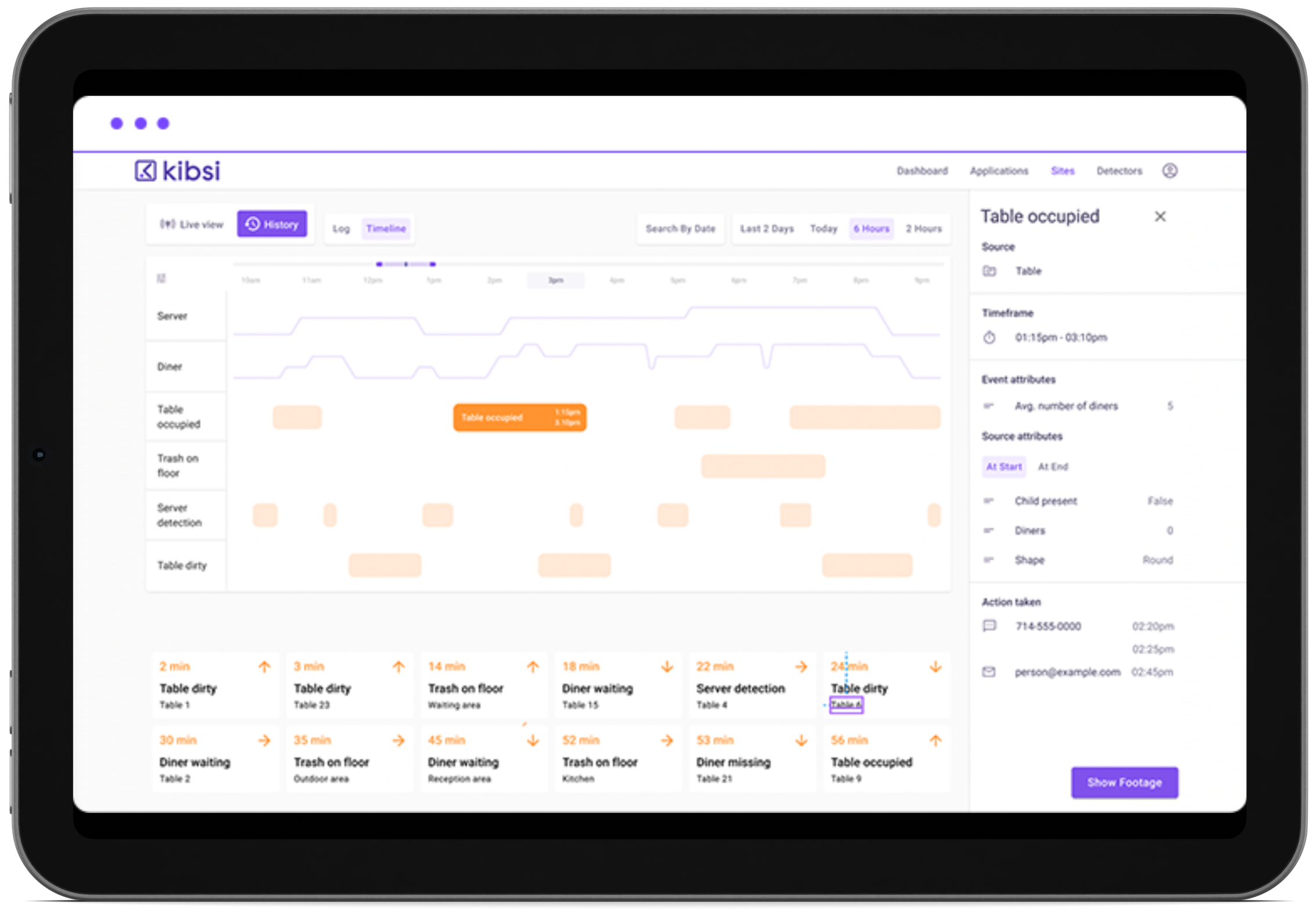

- Accuracy: In the domain of goods verification, precision is paramount. By minimizing human intervention at the initial stages of verification, Kibsi mitigates the typical risks associated with manual checks. Every barcode scanned and every SKU checked ensures that no product goes unaccounted for, and discrepancies are nearly eliminated.

- Efficiency: Warehouses are all about movement and flow. With Kibsi’s real-time verification, gone are the days of goods waiting in limbo, stuck in verification backlogs. As goods arrive, they’re processed instantly, accelerating the entire receiving operation and ensuring a smooth flow of products.

- Cost-Effective: It’s not just about saving time; it’s about saving money. When you trim down manual labor hours, you’re not only enhancing efficiency but also achieving significant cost reductions. Think of those 9,000 hours saved in terms of wages, benefits, and overhead costs. The financial advantages are clear and compelling.

- Integration: Transitioning to advanced technology can often feel daunting, especially with concerns about compatibility and integration hitches. Kibsi dispels these concerns. Designed with flexibility at its core, Kibsi seamlessly meshes with existing purchasing and inventory systems. The integration is so smooth, in fact, that the transition feels less like an overhaul and more like a natural evolution.

Conclusion

As industries evolve, so too must the strategies and technologies they employ. The logistics, distribution, and manufacturing sectors stand at a pivotal juncture, with manual processes steadily giving way to intelligent automation. Traditional methods, while tried and tested, are now being juxtaposed against the brilliant backdrop of technological progress. In this new era, video intelligence, as showcased by platforms like Kibsi, emerges as the vanguard.

Leaders in these sectors have a clear mandate: to champion change and drive their operations into the future. By embracing video intelligence:

- Operational Excellence: Organizations can transform fundamental processes, attaining levels of efficiency that were previously deemed unattainable. It’s an evolution from labor-intensive practices to streamlined, automated workflows.

- Risk Mitigation: With the reduction of human errors comes enhanced reliability. This means fewer discrepancies, fewer delays, and a bolstered reputation in the eyes of stakeholders and clients.

- Financial Prudence: Beyond the evident savings in labor costs, there are cascading financial benefits. Efficient operations reduce storage costs, minimize loss due to discrepancies, and potentially lead to better vendor and client relations, opening avenues for preferential rates and collaborations.

- Future-readiness: The industries of logistics, distribution, and manufacturing are not static; they are in constant flux, shaped by market dynamics, consumer behavior, and technological advancements. By integrating intelligent systems like Kibsi, organizations not only gain a competitive edge but also position themselves as forward-thinking pioneers, ready to embrace whatever the future holds.

In essence, it’s no longer just about navigating the present challenges—it’s about envisioning and shaping the future landscape of the industry. For leaders who are not content with mere participation but aim to lead the charge in this new era, the path is illuminated by technological partners like Kibsi. The future beckons, and it is bright with promise.