I. Introduction

Inventory management isn’t just about keeping track of what’s in the storeroom. It’s a complex dance of receiving, storing, and shipping goods, all while striving to maintain accuracy, efficiency, and customer satisfaction. But even the most careful dance can stumble, especially when human error and the intricacies of supply chains come into play.

This is where computer vision and video intelligence make their entrance, offering a harmonious blend of technology and practicality. These tools aren’t simply flashy new additions to the tech scene; they have the potential to transform inventory management from a laborious task into an automated, precise, and insightful process. To fully grasp the impact of this transformation, let’s explore the age-old problems in inventory management and the innovative solutions provided by these technologies, using the real-world experience of a global food & beverage distributor.

II. The Age-Old Problems of Inventory Management

Receiving Inventory:

- Human Mistakes: From miscounting to misplaced items, human errors during the receipt of goods can lead to big headaches down the line.

- Time-Consuming Manual Tracking: Logging each item individually is not only tedious but also prone to mistakes that can ripple throughout the entire supply chain.

Monitoring Inventory:

- Challenges in Real-Time Tracking: Without an eagle eye on every product, theft, damage, and misplacement can easily slip through the cracks.

- Manual Management Woes: The physical act of monitoring goods requires manpower and vigilance, often diverting attention from other critical business areas.

Sending Inventory:

- Errors in Dispatch: Incorrectly shipped items can lead to customer dissatisfaction, costly returns, and a muddled inventory count.

- The Labor of Manual Labeling: The tedious work of labeling each outgoing item can slow down the entire shipping process.

Supply Chain Complexity:

- A Chain of Challenges: Each of these factors contributes to an intricate supply chain. When one link wobbles, the entire chain can falter.

- Global Implications: In today’s interconnected markets, a small mistake in one area can have far-reaching consequences, affecting everything from local customer relationships to international trade agreements.

By exploring these fundamental challenges, we can better understand the demand for innovative solutions that not only address these problems but elevate the entire process of inventory management. Up next, we’ll see how computer vision and video intelligence are stepping into this role, offering not just a patch for existing issues, but a transformative upgrade for businesses of all shapes and sizes.

III. The Power of Computer Vision and Video Intelligence

Computer vision and video intelligence are more than just technological novelties. They present tangible solutions to the challenges that have long plagued inventory management. Let’s break down how these innovations are redefining each stage of the inventory process:

Accurate Receiving:

- Automated Monitoring: By employing computer vision, businesses can automatically track and verify incoming goods, dramatically reducing the chance of human error.

- Data Integration: The captured information can be seamlessly integrated into inventory systems, ensuring accurate and immediate updates.

Real-Time Monitoring:

Constant surveillance isn’t just for security; it’s essential for maintaining a solid inventory. With video intelligence:

- Goods are monitored 24/7, allowing for instant detection of any unauthorized movement or damage.

- Inventory levels are continuously tracked, triggering alerts for restocking or adjustments as needed.

Efficient Sending:

Shipping is where the inventory dance meets the customer, and it has to be flawless. With the aid of computer vision:

- Dispatch is streamlined, with real-time tracking and automatic labeling.

- Customer satisfaction is boosted, thanks to accurate and timely deliveries.

Data-Driven Insights:

Gone are the days when video footage was just for reviewing past events. Today’s technology converts these feeds into structured data, allowing for:

- In-depth analysis of inventory flow.

- Continuous improvement through actionable insights and trend recognition.

IV. A Real-World Example: Global Beverage Distributor

Introducing new technology into a business process is no small feat, especially in a field as complex as inventory management. Here’s how a global food and beverage distributor is finding success by embracing computer vision and video intelligence:

The Scenario:

The distributor faced numerous challenges in tracking inventory across various stages. Revenue loss from mislabeled deliveries, manual invoice disputes, and missing cases were more common than they would like to admit. The need for a more reliable, automated solution was clear.

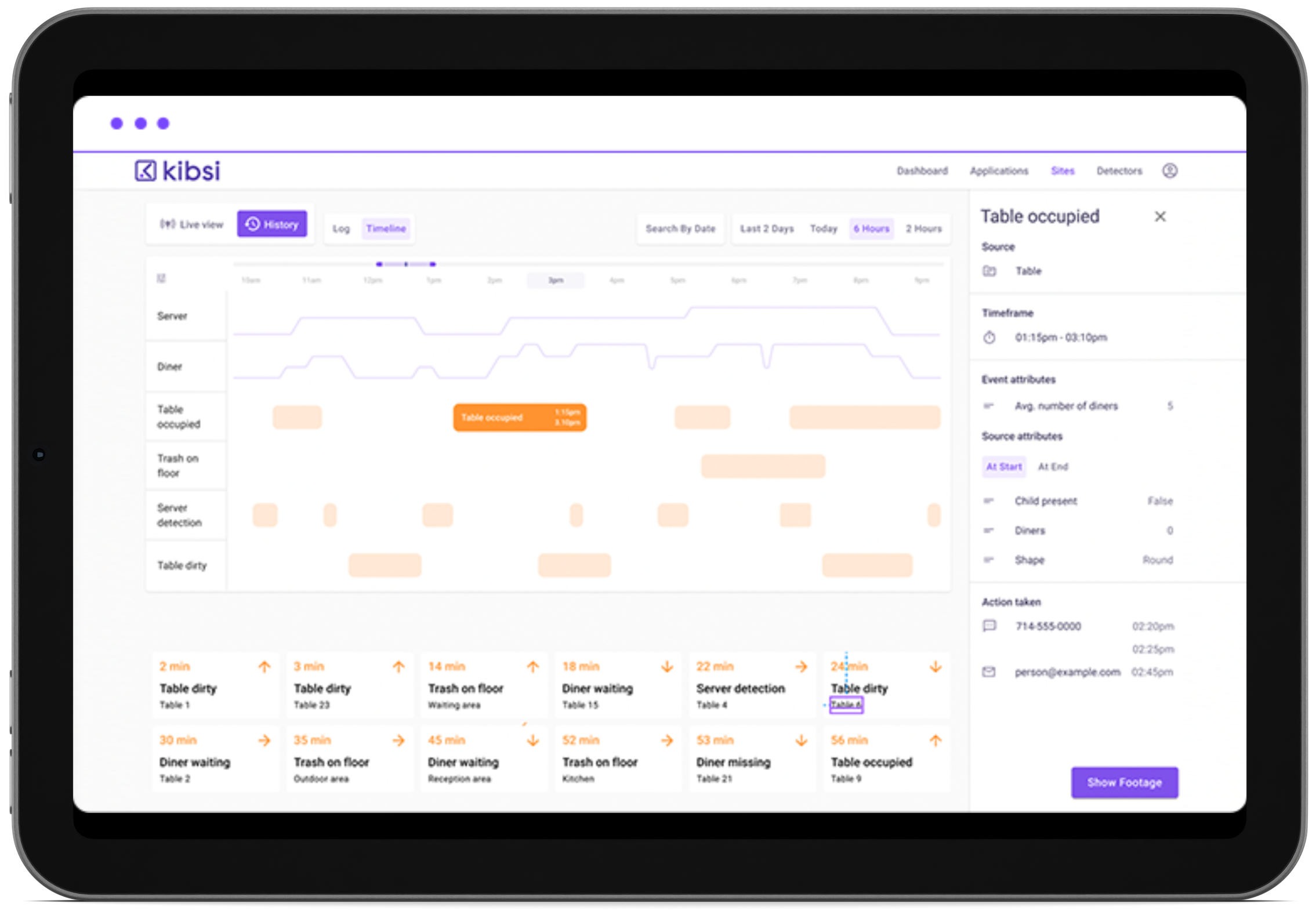

Implementing Kibsi:

Three business days after an introduction, the Kibsi team began discussing various possibilities. Here’s how computer vision is helping:

- Receiving: Counting and classifying cases as they arrive, increasing accuracy.

- Monitoring: Real-time tracking of inventory, ensuring no case goes missing.

- Sending: Enhancing the delivery process, including tracking cases off the trucks.

The Future Vision:

The collaboration is ongoing, with anticipation running high for the potential cost savings and efficiency gains. By integrating a solution like Kibsi, the beverage distributor is not just solving immediate problems but positioning itself for a more innovative, responsive future.

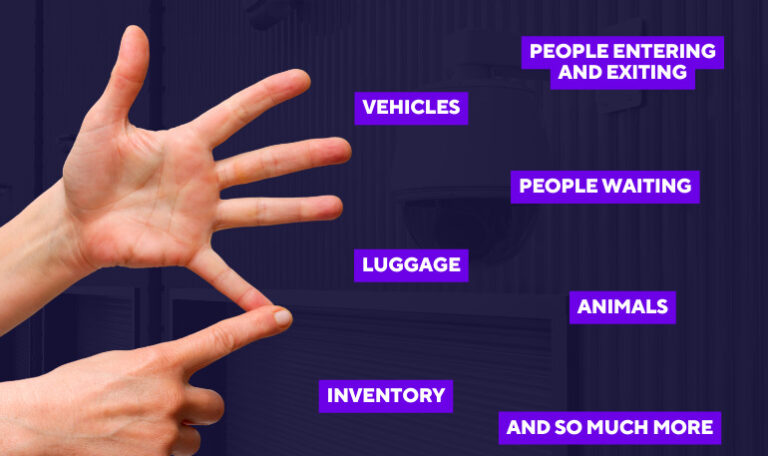

V. Computer Vision Beyond the Beverage Industry

The success of computer vision and video intelligence isn’t limited to just one industry. These technologies hold vast potential for various sectors, each with unique challenges and requirements:

Retail:

- Shelf Monitoring: Keep tabs on product availability and shelf presentation, enhancing customer experience.

- Theft Prevention: Real-time surveillance can pinpoint suspicious activities, reducing losses.

Manufacturing:

- Quality Control: Automated visual inspection ensures product quality, consistency, and adherence to standards.

- Safety Monitoring: Detect unsafe practices or conditions, promptly alerting staff to prevent accidents.

Healthcare:

- Patient Tracking: Monitor patient movement within facilities, enhancing care and safety.

- Equipment Utilization: Keep track of valuable medical equipment, ensuring optimal usage and availability.

Transportation & Logistics:

- Route Optimization: Analyze delivery paths, and dynamically adapt to changes, saving time and fuel.

- Warehouse Efficiency: Manage and track goods in vast warehouses with precision, reducing delays, and mishaps.

These examples demonstrate the versatility and adaptability of computer vision, capable of meeting diverse industry needs with tailored solutions.

VI. Conclusion

Inventory management, a process once beleaguered by manual labor, inaccuracies, and inefficiencies, is entering a new era. Computer vision and video intelligence, embodied by platforms like Kibsi, are not merely patching up old problems but paving the way for a more intelligent, responsive, and profitable business landscape.

Whether it’s a global beverage distributor seeking to prevent revenue loss or a retailer aiming to enhance shelf appeal, the applications of these technologies are broad and compelling. With real-time tracking, automated accuracy, and actionable insights, computer vision is no longer a futuristic dream but a present-day reality, turning ordinary video feeds into a treasure trove of business intelligence.

The future of inventory management is here, and it’s bright, agile, and brimming with potential. Those who embrace this technological shift stand to see their business not just survive but thrive in a world that values precision, efficiency, and innovation.