Introduction

The intersection of Artificial Intelligence (AI) and supply chain management is creating a new frontier for operational efficiency. Leading the charge in this technological evolution is Computer Vision. This innovative AI subset is not just enhancing existing processes; it’s redefining them. Today, we’re exploring how various applications of Computer Vision are transforming supply chain operations, offering insights into a future where precision, efficiency, and safety are paramount.

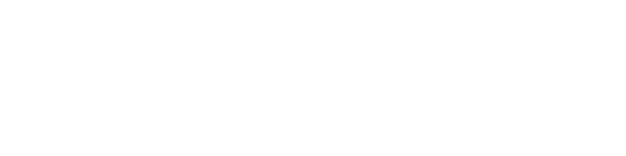

1. Arrival Monitoring: The First Step in Supply Chain Precision

When goods arrive at a facility, the clock starts ticking. Efficient management of this initial stage is essential to keep the supply chain moving smoothly. With Computer Vision technologies, arrival monitoring becomes a symphony of precision and timing. By integrating with existing systems, Computer Vision provides real-time data on the arrival of goods, matching them against expected shipments and inventories. This integration not only ensures accuracy in record-keeping but also flags any discrepancies immediately, allowing for quick resolution. It’s a modern solution that preserves the integrity of the supply chain, ensuring that the right goods are at the right place at the right time.

2. Wait Timer: Revolutionizing Loading Dock Efficiency

The loading dock is the heartbeat of a warehouse, a place where every second counts. The traditional approach to managing this crucial point often leads to bottlenecks and delays. Enter Computer Vision, which transforms loading docks into models of efficiency. By monitoring arrival and wait times, Computer Vision systems can predict and alert when docks are about to become free, allowing for a seamless transition between shipments. This real-time data helps businesses keep their promises to customers, with faster turnover rates that lead to increased satisfaction and productivity.

3. Forklift Operations: Enhancing Safety and Streamlining Movement

Forklifts are the workhorses of warehouse operations, but they can also pose significant safety risks if not properly managed. Computer Vision serves as an omnipresent supervisor, continuously monitoring forklift movements. It ensures that operators adhere to safety protocols and helps in planning optimal routes through the warehouse maze. This not only reduces the risk of accidents but also improves the overall flow of operations. With Computer Vision, forklifts become smarter, operators become safer, and warehouses become more efficient.

4. Heatmaps & Traffic: Mapping the Path to Operational Excellence

Understanding the flow of traffic within a warehouse can unlock new levels of operational efficiency. Computer Vision goes beyond simple observation, creating heatmaps that illustrate the movement patterns of people, equipment, and goods. These visual tools are invaluable for managers looking to optimize their floor plans and processes. By analyzing these heatmaps, businesses can reconfigure layouts to improve safety, reduce travel time for employees, and enhance the overall productivity of operations.

5. Quality Control: Upholding Standards at Every Step

Quality control is the guardian of a brand’s reputation, and in the fast-paced world of supply chains, there’s no room for error. Computer Vision offers a set of vigilant eyes that never tire, continuously scanning products for defects or abnormalities. This high-tech approach to quality control ensures that every item that leaves the warehouse meets the company’s stringent standards. By relying on Computer Vision, businesses can uphold their commitment to quality, solidifying customer trust and satisfaction.

6. Label Scanning: The Key to Inventory Intelligence

In the intricate dance of supply chain management, every item must be accounted for, and labels are the language of logistics. Computer Vision simplifies label scanning, accurately capturing data and seamlessly feeding it into inventory management systems. This process provides a comprehensive view of the inventory, reducing errors, and enhancing the traceability of every item. With Computer Vision, label scanning becomes a cornerstone of a smart, data-driven supply chain that thrives on accuracy and integration.

7. Safety & PPE Compliance: A Vision for a Safer Workplace

Safety is paramount, and in the world of logistics, maintaining high safety standards is a complex, ongoing task. Computer Vision aids in this essential duty by continuously monitoring the use of Personal Protective Equipment (PPE) and ensuring compliance with safety protocols. This proactive surveillance helps to prevent accidents before they happen and provides a safer environment for workers, which is ultimately reflected in the efficiency and morale of the entire operation.

8. Gauge Reading: Precision in Every Measurement

Accuracy in gauge reading is vital for maintaining equipment and ensuring operational efficiency. Computer Vision automates the process of visual inspections and gauge readings, removing the possibility of human error and providing precise, reliable data. This precision is crucial for making informed decisions about maintenance and workflow, ensuring that machinery operates at peak efficiency and that any potential issues are addressed proactively.

9. Delivery & Dispatch: The Final Link in the Supply Chain

The culmination of the supply chain’s efforts is the delivery and dispatch of goods, where precision is the name of the game. Computer Vision oversees this critical phase, ensuring that every package is accounted for and that deliveries are accurate. This meticulous oversight leads to a streamlined dispatch process, timely deliveries, and ultimately, satisfied customers. Computer Vision stands as a testament to a business’s commitment to excellence, right down to the last detail.

Conclusion

Computer Vision is more than just a technological tool; it’s a strategic asset in the modern supply chain. It provides comprehensive oversight and a level of precision that traditional methods simply cannot match. As we move forward, the integration of Computer Vision in supply chain operations will not only become more prevalent but also essential for businesses looking to thrive in an increasingly competitive landscape.

Ready to bring the power of Computer Vision to your supply chain operations? Contact us to learn more about how this technology can revolutionize your business. Visit our website to explore further resources and to understand the full scope of our Computer Vision solutions. Let’s build a smarter, safer, and more efficient future together.