Introduction

In the bustling world of manufacturing and distribution, the efficiency of loading docks stands as a crucial determinant of overall operational success. These vital hubs, where goods are continuously loaded and unloaded, are the linchpins in the complex machinery of logistics operations. However, these crucial nodes in the supply chain are often beset with challenges that can lead to substantial operational delays, escalated costs, and serious safety risks.

Amidst these challenges, computer vision technology is rising as a transformative beacon in the realm of logistics. This innovative technology, which empowers machines to interpret and process visual data from the real world, is revolutionizing the management of logistics operations. By automating processes and enhancing visibility, computer vision transcends being a mere futuristic concept and stands as a practical, cutting-edge tool that is reshaping the landscape of manufacturing and distribution today.

7 Challenges at Loading Docks and the Role of Computer Vision

1. Idle Trucks and Scheduling Inefficiencies

Trucks lingering idly at loading docks not only lead to increased operational costs but also contribute to a decrease in overall efficiency. A concerning finding from the U.S. Department of Transportation highlights that prolonged wait times at loading docks elevate crash risks by 6.2%. Moreover, these inefficiencies can incur costs of up to a staggering $1.1 billion annually in extensive operations. The introduction of computer vision technology promises a significant reduction in these wait times and associated costs by optimizing truck scheduling and dock usage with real-time data analysis and predictive modeling.

2. Mishandling and Incorrect Loading of Products

The mishandling of products at loading docks often culminates in incorrect loading, a problem that nearly half of warehouses are striving to address. By 2024, intelligent automation is seen as a pivotal solution to this challenge. Computer vision systems, with their advanced image recognition capabilities, can ensure the accurate and efficient loading of products, thereby minimizing errors and enhancing operational accuracy.

3. Safety Hazards

An alarming statistic reveals that loading docks are the scene of 25% of all industrial accidents, accompanied by a high rate of near-misses. The introduction of computer vision technologies in these high-risk zones can drastically reduce the occurrence of accidents. These systems are capable of real-time monitoring of the loading dock area, promptly detecting potential hazards, and alerting staff, thereby significantly increasing the overall safety of operations.

4. Security Concerns

The security of loading docks is paramount, given their vulnerability to threats such as theft and unauthorized access. In this high-stakes environment, computer vision emerges as a formidable ally, offering enhanced surveillance capabilities far beyond traditional methods. These systems utilize sophisticated image recognition algorithms to continuously monitor the dock area. They are adept at detecting any unauthorized access or suspicious activities, immediately alerting the relevant authorities or management teams. This advanced level of surveillance not only deters potential security breaches but also contributes to a safer and more secure operational environment. By ensuring that only authorized personnel and vehicles have access to the docks, computer vision helps maintain the integrity of the entire supply chain.

5. Operational Inefficiencies

Traditional methods in loading dock operations often lead to bottlenecks and inefficiencies that can ripple through the entire supply chain. Computer vision technology addresses these challenges head-on by enabling a more streamlined and efficient operational workflow. It does so through advanced data analysis and image processing capabilities, which provide real-time insights into various aspects of dock operations. These insights include load verification, vehicle and personnel tracking, and time-stamped activity logs. By harnessing these data-driven insights, managers can make informed decisions that optimize workflow, reduce turnaround times, and increase overall throughput, leading to enhanced operational efficiency and productivity.

6. Compliance and Reporting

In the logistics industry, adherence to safety and operational standards is not just a best practice but often a legal requirement. Computer vision plays a critical role in ensuring compliance at loading docks. It does so by providing a comprehensive visual record of activities, which can be crucial for audits and regulatory compliance. This technology monitors for compliance with safety protocols, such as the proper use of personal protective equipment and adherence to operational guidelines. Additionally, it aids in the documentation process, automating the creation of reports and logs that are essential for regulatory submissions. This not only saves time and resources but also provides a more accurate and reliable record for compliance purposes.

7. Data Accessibility and Real-Time Feedback

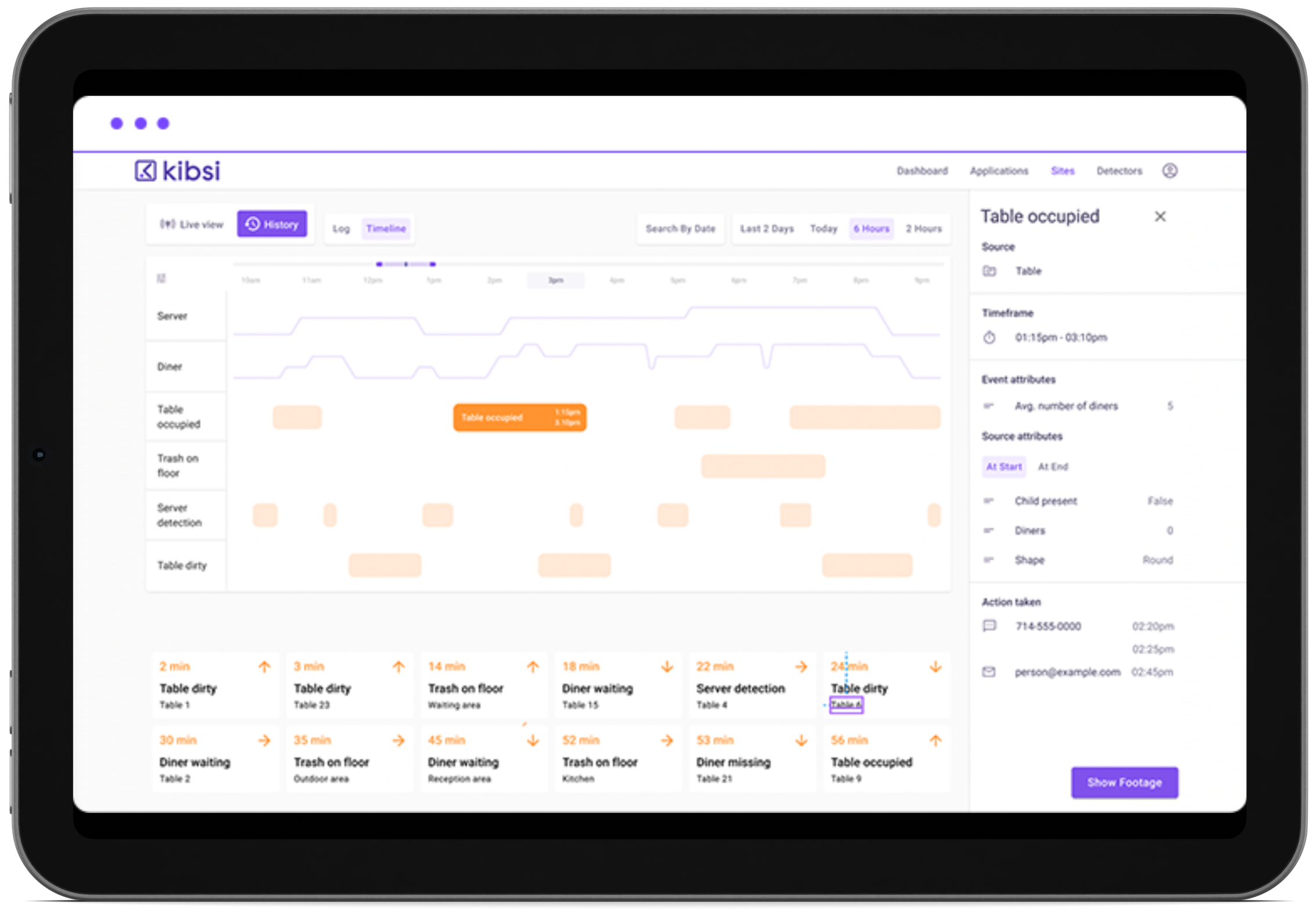

In the dynamic and fast-paced environment of loading docks, the ability to access real-time data is critical for maintaining operational agility and responsiveness. Computer vision systems excel in this area by providing immediate feedback and actionable insights. These systems analyze visual data from the docks in real-time, offering a clear view of the current operations, identifying bottlenecks, and suggesting optimization strategies. This capability allows managers to make swift, data-driven decisions to adjust operations as needed, enhancing the overall efficiency and responsiveness of the dock operations. The real-time nature of this data is invaluable in adapting quickly to changing circumstances, ensuring that the loading docks operate at peak efficiency at all times.

Computer Vision + AI = Solution for Your Loading Dock Challenges

As we delve deeper into the realm of enhancing loading dock operations, the name that emerges as a comprehensive solution is Kibsi. Kibsi stands out as an end-to-end computer vision platform, tailored to address the intricate challenges of loading docks and truck management.

Kibsi’s Tailored Approach to Loading Docks

Kibsi’s platform is designed with the specific needs of loading docks in mind. Its capabilities range from automating scheduling and traffic management to ensuring the safety and security of the premises. By utilizing advanced AI algorithms, Kibsi can process and analyze visual data in real-time, providing actionable insights to streamline operations. Whether it’s managing the influx of trucks, optimizing dock usage, or ensuring compliance with safety protocols, Kibsi’s versatile platform is equipped to handle these tasks efficiently.

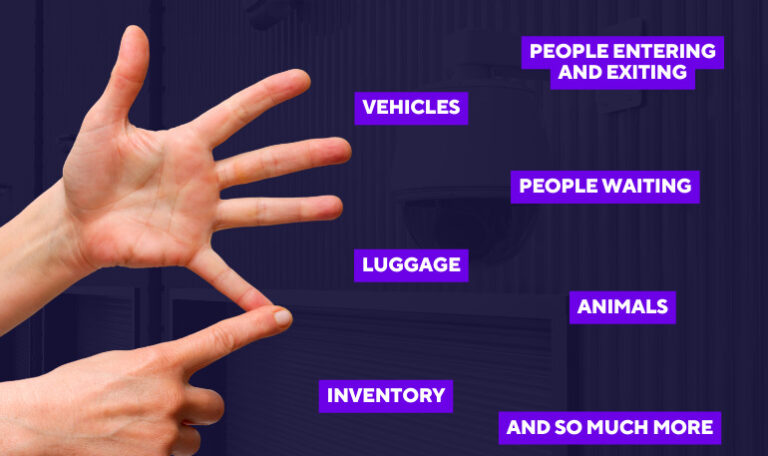

Kibsi’s Capabilities

While Kibsi is a powerful tool, the focus remains on its ability to integrate seamlessly into existing systems, enhancing and complementing current operational procedures. Its strength lies in its adaptability, providing a customizable solution that can evolve with the changing dynamics of logistics and supply chain environments.

Integrating Computer Vision with Existing Systems

Seamless Integration with Current Logistics Systems

One of the strengths of computer vision technology is its adaptability and ease of integration with existing logistics systems. Modern computer vision platforms are designed to be plug-and-play, allowing them to be seamlessly incorporated into the existing technological infrastructure. This integration capability ensures that businesses can adopt computer vision without overhauling their current systems, making the transition smooth and cost-effective.

Role of AI and Machine Learning in System Adaptability

The backbone of computer vision’s success in logistics is its reliance on AI and machine learning. These technologies enable the system to learn and adapt over time, continually improving its accuracy and effectiveness. For example, machine learning algorithms can analyze past traffic patterns to optimize future dock scheduling. Similarly, AI can learn to identify new types of safety hazards, enhancing the system’s ability to protect workers and goods continually. This constant learning and adaptation make computer vision an ever-evolving asset in the logistics industry.

Conclusion

The integration of computer vision technology in logistics, especially in the domain of loading docks, marks a transformative era in this sector. The potential of these technologies to revolutionize operations is immense, from optimizing efficiency and reducing wait times to ensuring unparalleled safety and security.

Platforms like Kibsi offer a glimpse into a future where logistics operations are more streamlined, secure, and efficient. As the industry evolves, the adoption of such technologies is not just an option but a necessity for those looking to stay ahead in the competitive landscape of manufacturing and distribution.

Embracing the change, harnessing the potential of computer vision, and transforming loading dock operations into models of efficiency and safety is proving to be a valuable initiative for many organizations. To explore how Kibsi can specifically benefit your operations, we invite you to learn more about our platform. Discover the future of logistics technology today. Request a demo or get in touch with our team for more information.