AI COMPUTER VISION SOLUTION

See your processes clearly and optimize everything

Unlock the power of AI and computer vision for advanced process monitoring

Table of Contents

Using Computer Vision for Process Monitoring

What is process monitoring?

Understanding process monitoring and its impact

In the industrial world, maintaining smooth and efficient operations is paramount. This is where process monitoring comes into play. It’s the systematic observation and analysis of the steps involved in a particular operation or function. Imagine it as taking a close look under the hood of your industrial processes to identify areas for improvement and ensure everything is running as intended.

Process monitoring involves gathering data about various aspects of an operation, such as:

- Machine performance

- Production rates

- Quality control checks

- Inventory levels

- Worker activity

By analyzing this data, companies can gain valuable insights into how their processes are performing. This allows them to identify:

- Bottlenecks that are slowing down production

- Deviations from quality standards

- Areas where safety protocols might not be strictly followed

- Opportunities to streamline workflows

In essence, process monitoring empowers organizations to take a proactive approach to optimizing their industrial operations.

How do AI and computer vision improve process monitoring?

Technology that cuts costs and improves efficiency

Traditional process monitoring methods often rely on manual observation or data collection, which can be time-consuming, prone to human error, and limited in scope. Here’s where Artificial Intelligence (AI) and Computer Vision come in, offering a significant leap forward in industrial process monitoring.

Computer vision: capturing key details

CV utilizes high-definition cameras and advanced algorithms to capture and analyze visual data in real-time. This allows computer vision solutions to monitor various aspects of industrial processes, such as:

- Presence or absence of objects: Ensuring parts are present on an assembly line or verifying inventory levels in a warehouse.

- Object positioning and orientation: Confirming proper product placement on pallets or detecting deviations from designated storage locations.

- Activity tracking: Monitoring worker adherence to safety protocols or identifying bottlenecks in workflows.

AI extracting meaningful insights: The visual data captured by computer vision becomes truly powerful when combined with AI’s analytical capabilities. AI algorithms can interpret the data, identify patterns, and detect anomalies that might be difficult for humans to spot in real-time. Imagine AI flagging missing components on an assembly line or identifying a potential safety hazard based on worker activity.

The Benefits of This Powerful Combination

By working together, AI and computer vision offer significant advantages over traditional methods:

Real-time monitoring & alerts

Continuous monitoring provides real-time insights and enables immediate alerts for potential issues.

Strengthened compliance and safety

Monitor adherence to safety protocols and regulations to help prevent accidents and maintain a safe working environment.

Improved efficiency and productivity

Identify bottlenecks and inefficiencies to empower organizations to streamline workflows and optimize production processes.

Enhanced accuracy and objectivity

Eliminate human error and bias from the monitoring process, generating to more accurate and reliable data.

In essence, AI and computer vision empower organizations to gain a deeper understanding of their industrial processes, leading to significant improvements in efficiency, quality control, and overall operational performance. This technology offers a powerful tool for companies to optimize their industrial operations.

What are industries that can benefit from AI and computer vision advancements in process monitoring?

A singular solution for an array of industries

The transformative potential of AI and computer vision extends across a wide range of industries that rely on efficient and well-controlled processes. Here are some key examples:

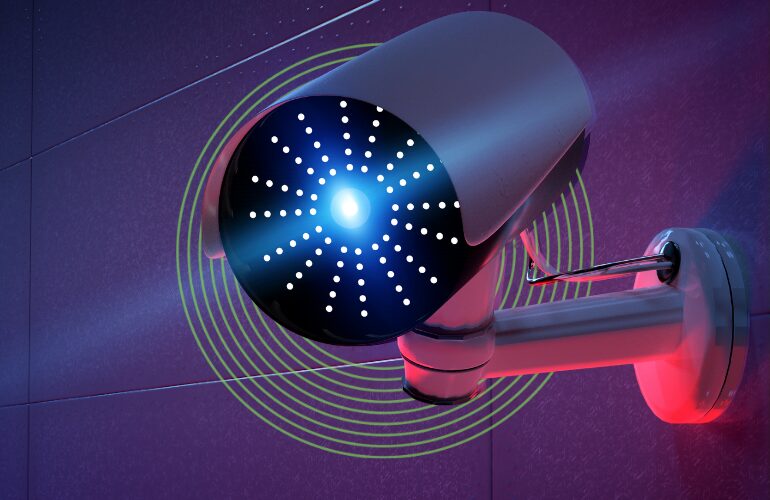

Manufacturing

From ensuring precise assembly line operations and identifying defective products to monitoring equipment health and preventing downtime, AI and computer vision empower manufacturers to achieve higher quality control, optimize production efficiency, and minimize waste.

Warehousing

Optimizing warehouse space utilization, automating inventory management, and expediting order fulfillment processes are all areas where AI and computer vision can significantly improve efficiency in warehouses. Additionally, real-time monitoring of warehouse activity can enhance security and prevent potential theft or damage to goods.

Automotive

From automating visual inspections on assembly lines to monitoring robot movements and identifying potential safety hazards, AI and computer vision are transforming the automotive industry. This technology plays a crucial role in ensuring the quality and safety of vehicles at every stage of production.

Pharmaceuticals

In highly regulated industries like pharmaceuticals, ensuring precise adherence to production protocols and identifying potential contamination risks are paramount. AI and computer vision offer the accuracy and real-time monitoring capabilities needed to maintain the highest quality standards in pharmaceutical manufacturing.

Supply chain and logistics

Real-time tracking of inventory movement, verification of product loading and unloading accuracy, and automated identification of damaged goods during transport are just a few ways AI and computer vision can revolutionize supply chain and logistics. This translates to faster delivery times, reduced losses, and improved overall supply chain transparency.

Food and Beverage Production

Maintaining stringent hygiene standards, ensuring food safety regulations are met, and automating quality control checks throughout the production process are crucial aspects in food and beverage production. AI and computer vision solutions can effectively address these needs, safeguarding food quality and consumer health.

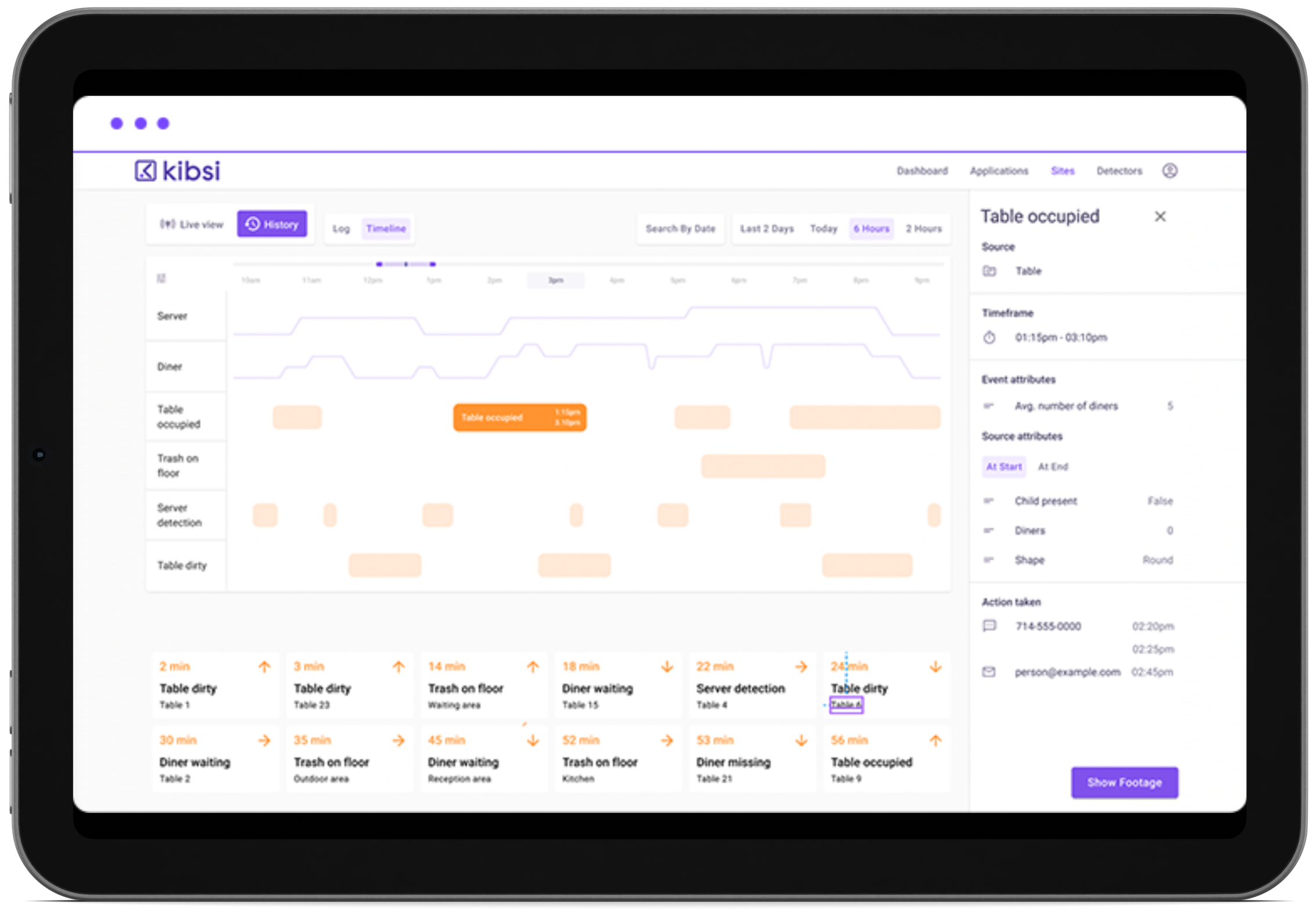

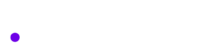

How does Kibsi help with process monitoring?

Simplicity meets capability in a robust computer vision platform

- Tailored Solutions: Kibsi understands that every industry and process has unique monitoring needs. Kibsi’s platform offers the flexibility to be customized with specific algorithms and functionalities to address your particular challenges. Whether it’s ensuring proper assembly line procedures in manufacturing or monitoring forklift operations in a warehouse, Kibsi can be configured to deliver the insights you need.

- Real-time Monitoring and Alerts: Kibsi leverages computer vision to provide continuous monitoring of your industrial processes. This real-time data stream allows for immediate identification of potential issues, enabling you to take corrective actions swiftly and minimize downtime. Imagine Kibsi generating an alert if a safety hazard is detected in a work zone, allowing for swift intervention to prevent accidents.

- Actionable Insights: Kibsi goes beyond simply providing raw visual data. The platform’s AI capabilities analyze the captured data and translate it into actionable insights. This could involve highlighting deviations from standard procedures, identifying bottlenecks in workflows, or flagging potential equipment malfunctions. These insights empower you to make data-driven decisions to optimize your processes and ensure smooth operations.

- User-friendly Interface: Kibsi recognizes that ease of use is critical for widespread adoption. The platform boasts a user-friendly interface that requires minimal technical expertise to operate. This allows your team to focus on utilizing the insights provided by Kibsi, rather than struggling with complex configurations.

- Scalability and Integration: Kibsi’s platform is designed to scale with your growing needs. Whether you’re a small manufacturing facility or a large-scale logistics operation, Kibsi can accommodate your specific requirements. Additionally, the platform integrates seamlessly with existing systems, ensuring a smooth integration into your current workflow.

Connect cameras

Identify and train for processes

Map monitoring area

Select output

Frequently Asked Questions (FAQs)

Quick answers to common questions

AI and computer vision can be used to monitor a wide range of data in industrial processes. This includes:

- Visual data: Presence or absence of objects, object location and orientation, activity tracking of workers or machines.

- Sensor data: Machine temperature, vibration levels, energy consumption (when integrated with existing sensors).

By combining visual and sensor data, Kibsi’s AI platform can provide a holistic view of your processes, enabling you to identify issues that might be missed by traditional monitoring methods.

AI and computer vision can significantly enhance quality control by automating visual inspections. Kibsi’s platform can be trained to identify defects in products or deviations from standard procedures, ensuring consistent quality throughout your processes. This reduces the risk of defective products reaching customers and helps maintain a high level of quality control.

Absolutely! AI can analyze data captured by computer vision to identify areas where workflows slow down. For instance, Kibsi might detect congestion points on a conveyor belt or delays in worker activity. This allows you to pinpoint bottlenecks and implement targeted solutions to streamline your processes and improve overall efficiency.

AI and computer vision can be instrumental in enhancing safety in industrial environments. Kibsi’s platform can be configured to monitor for unsafe work practices, such as workers not wearing proper personal protective equipment (PPE). Additionally, it can detect potential equipment malfunctions that could pose safety hazards. By providing real-time alerts for these situations, Kibsi empowers you to take proactive steps to prevent accidents and ensure a safe working environment.

In most cases, Kibsi’s solutions can leverage existing high-definition security cameras already installed in your facilities. This minimizes the need for additional hardware investment. However, depending on your specific needs, Kibsi can also advise on the most suitable camera configurations to optimize the effectiveness of the AI and computer vision technology.

Kibsi’s platform is designed for ease of use and rapid deployment. Our team of experts will handle the installation and configuration process, ensuring a smooth integration with minimal disruption to your operations. Typically, Kibsi’s solutions can be up and running within a short timeframe, allowing you to start reaping the benefits of AI-powered process monitoring quickly.

Kibsi prioritizes data accuracy. Our AI models are rigorously trained on vast datasets relevant to your industry and specific processes. Additionally, Kibsi allows for ongoing customization and fine-tuning of the AI models to ensure they continue to deliver highly accurate results over time.

Kibsi offers flexible pricing plans to suit your specific needs and budget. We can discuss these options in detail during your free consultation. Kibsi’s pricing structure is designed to be transparent and ensure a clear return on investment through improved efficiency, reduced waste, and enhanced safety within your industrial processes.

How Does Kibsi Work in Your World?

Kibsi is designed to flex to your needs, offering real-time alerts, easy customization, and seamless API integration. Whether it’s tracking freight, monitoring manufacturing or keeping queues moving for concessions, Kibsi turns your video feeds into actionable insights. Intrigued? There’s a lot more to explore.

Hot off the Press: Articles and News

I. Introduction The interest in AI technologies, particularly computer vision (CV), has skyrocketed in recent years. Companies in manufacturing, supply chain, and logistics are eager to explore AI’s potential to transform their operations. According to …

Security cameras have been a fixture in manufacturing plants, warehouses, and distribution centers for years, diligently watching over operations to prevent theft and ensure safety. But as technology has advanced, these once-passive sentinels have evolved …

Introduction In recent years, the manufacturing industry has been undergoing a significant transformation, driven by the rapid advancement of technology and the growing demand for more efficient, sustainable, and human-centric production processes. As we move …

In a recent survey conducted by Kibsi, an astonishing 91% of manufacturing and supply chain professionals expressed their belief that AI will have a notable impact on their industries and, of those, 67% expect that …

When it comes to industries like manufacturing, supply chain, and logistics, computer vision technology is revolutionizing operations by enabling automated systems to interpret and act on visual data. As these industries face increasing demands for …

Is AI a revolution or a fad for traditional industries? Artificial intelligence (AI), particularly computer vision, is creating a stir in manufacturing and logistics. While some leaders are enthusiastic about its potential to streamline operations …

Navigating the ever-expanding web of regulations can feel like running an obstacle course blindfolded. Regulatory compliance across industries – from food and beverage manufacturing to pharmaceuticals and automotive – has become a critical but often …

The specter of automation replacing human jobs has haunted the manufacturing and logistics industries for decades. With the rise of artificial intelligence (AI) and, particularly, computer vision, these concerns have reached a fever pitch. However, …

The countdown to MODEX 2024 is on, and the excitement at Kibsi is palpable! This year, we’re not just attending; we’re showcasing our innovative no-code computer vision platform at Booth #A9911 in Building A. It’s …

The Defect in Defects in Manufacturing Defects in manufacturing can be a costly affair, affecting everything from production efficiency to brand reputation. The ripple effect of undetected defects extends throughout the supply chain, ultimately impacting …