AI COMPUTER VISION SOLUTION

Optimimize your loading docks with computer vision

Enhance safety, efficiency, and productivity at your loading docks with real-time monitoring, automated alerts, and actionable insights

Table of Contents

Using Computer Vision for Loading Docks

What is loading dock optimization?

Definition and importance

Loading dock safety and efficiency are critical aspects of supply chain management that impact a business’s overall productivity, profitability, and reputation. Loading docks are the gateways through which goods enter and exit a facility, and optimizing their operations is essential for maintaining a smooth flow of materials and minimizing disruptions.

Loading dock safety refers to the measures and practices implemented to prevent accidents, injuries, and damage to property at loading docks. These measures include proper equipment usage, adherence to safety protocols, and the provision of adequate training to dock workers. Loading dock efficiency, on the other hand, focuses on optimizing the flow of goods and minimizing delays during the loading and unloading process. Efficient loading docks can reduce truck wait times, improve inventory accuracy, and increase overall throughput.

Common Safety Hazards at Loading Docks:

- Forklift accidents: Forklifts are commonly used at loading docks, and their operation poses a significant safety risk. Accidents can occur due to factors such as improper training, speeding, and inadequate visibility.

- Slips, trips, and falls: Loading docks often have uneven surfaces, slippery floors, and obstacles that can lead to slips, trips, and falls. These incidents can result in injuries ranging from minor bruises to severe fractures.

- Struck-by incidents: Loading docks are busy areas with moving vehicles and equipment. Workers can be struck by forklifts, trucks, or falling objects, leading to serious injuries or even fatalities.

- Repetitive strain injuries: Loading and unloading goods can involve repetitive and strenuous tasks, which can strain muscles and joints. Over time, these strains can lead to chronic musculoskeletal injuries.

- Exposure to hazardous materials: Loading docks may handle hazardous materials, such as chemicals or flammable substances. Improper handling or storage of these materials can also pose a health risk to workers.

Inefficiencies:

- Truck congestion and delays: Inefficient dock scheduling and management can lead to truck congestion and delays. This can result in lost productivity, increased demurrage costs, and customer dissatisfaction.

- Mishandling of goods: Improper loading and unloading techniques can damage goods, leading to lost inventory and customer complaints.

- Incorrect loading and unloading: Errors in loading and unloading can result in incorrect product quantities, misplaced items, and delays.

- Lack of visibility into dock operations: Manual tracking of dock operations can lead to a lack of visibility and control, making it difficult to identify and address inefficiencies.

Impact of Loading Dock Incidents on Businesses

Loading dock incidents can have a significant impact on businesses, leading to:

- Lost productivity: Injuries, damage to goods, and equipment downtime can disrupt operations and reduce productivity.

- Increased insurance premiums: A history of loading dock incidents can lead to higher insurance premiums.

- Damage to goods and equipment: Mishandling of goods and equipment can result in damage or loss, leading to financial losses.

- Reputational damage: Loading dock incidents can damage a business’s reputation and customer trust.

- Legal liability: Businesses can be held legally liable for injuries or damages caused by loading dock incidents.

By adopting a comprehensive approach to loading dock optimization, businesses can reap significant benefits and gain a competitive edge in today’s fast-paced supply chain environment.

How do AI and computer vision improve loading docks?

Technology that cuts costs and improves efficiency

Optimizing loading dock operations requires a keen eye for detail and the ability to analyze vast amounts of data. This is where AI and computer vision come together as a powerful team, forming a symbiotic relationship that takes the guesswork out of dock management.

Computer Vision: Seeing the Big Picture

Imagine a network of strategically placed high-definition cameras constantly capturing activity at your loading dock. These cameras act as the eyes of the system, providing a continuous stream of visual data. Computer vision is the technology that transforms this visual data (like video footage) into a format that computers can understand. It does this through a combination of techniques including image recognition, object detection, and motion analysis. By extracting meaningful data from video footage, computer vision lays the groundwork for AI to perform its analytical magic.

AI: Making Sense of the Visual Data

Once computer vision captures the visual data, AI steps in to analyze it and unlock its potential. AI, or Artificial Intelligence, is the brain behind the operation. It utilizes complex algorithms to analyze the data collected by computer vision, identifying patterns, trends, and anomalies. For instance, AI can recognize specific types of trailers, track their movements around the loading dock, and estimate loading and unloading times. This empowers dock managers to make data-driven decisions that optimize dock utilization and workflow efficiency.

By working together, AI and computer vision unlock a wealth of insights for optimizing your loading dock:

Real-time visibility and analytics

Track trailers, monitor progress, identify bottlenecks for improved efficiency.

Enhanced safety measures

Detect hazards, monitor worker activity, eliminate blind spots to prevent accidents.

Optimized scheduling and resource allocation

Schedule dock doors, deploy resources in real-time for peak efficiency.

Increased accuracy and verification

Verify loading, automate data collection to minimize errors.

In short, computer vision captures every detail of activity at your loading dock. AI then takes center stage, analyzing this visual data to extract valuable insights. This powerful combination empowers you with real-time visibility, improved safety measures, enhanced accuracy, and optimized scheduling – all contributing to a significantly more efficient and streamlined loading dock operation.

What are industries that can benefit from AI and computer vision advancements for loading dock optimization?

A singular solution for an array of industries

Efficient loading dock operations are the lifeblood of numerous industries. Here’s how AI and computer vision can revolutionize loading dock operations across various sectors:

Manufacturing

Manufacturing facilities constantly strive to optimize production cycles and minimize downtime. AI and computer vision can streamline loading dock activities, ensuring a smooth flow of raw materials coming in and finished products going out. This translates to faster production cycles, reduced equipment downtime waiting for materials, and improved inventory control through real-time dock visibility.

Warehousing

Warehouses juggle the critical task of fulfilling orders efficiently while maximizing space utilization. AI and computer vision can significantly streamline order fulfillment by tracking incoming and outgoing shipments, optimizing dock door scheduling, and identifying potential bottlenecks in the loading/unloading process. This leads to faster order fulfillment times, improved space utilization within the warehouse, and enhanced safety for workers by reducing congestion around loading docks.

Supply chain and logistics

The success of logistics companies hinges on on-time deliveries and cost-effective transportation. AI and computer vision can empower logistics companies to achieve these goals by providing real-time visibility into trailer arrivals and departures at loading docks. This allows for optimized scheduling, reduced transportation costs through efficient dock utilization, and increased visibility into the overall supply chain, ensuring timely deliveries.

Food and Beverage Production

The food and beverage industry faces stringent regulations regarding food safety and temperature control. AI and computer vision can be instrumental in ensuring compliance by monitoring loading dock activities for potential food safety risks, maintaining efficient temperature control for perishable goods, and ultimately, reducing product spoilage.

The benefits of AI and computer vision extend far beyond a single industry. From the fast-paced world of manufacturing to the temperature-sensitive realm of food and beverage, these technologies offer a powerful solution for optimizing loading dock operations. Regardless of your industry, AI and computer vision can empower you to streamline processes, enhance safety, and achieve significant cost savings, propelling your business towards a future of efficient and optimized loading dock management.

How does Kibsi help with forklift safety?

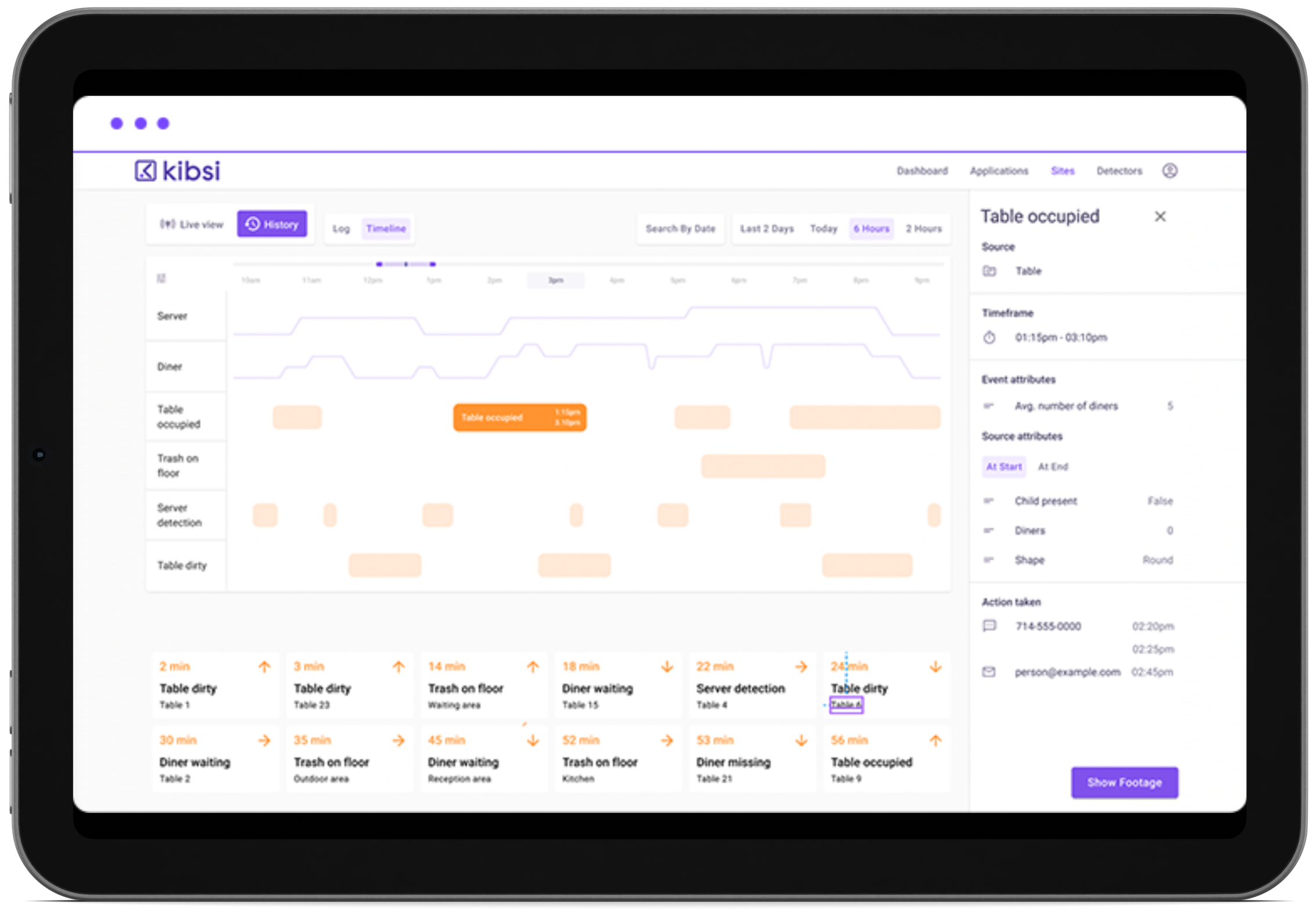

Simplicity meets capability in a robust computer vision platform

Traditional loading dock operations are often plagued by inefficiencies, safety concerns, and a lack of real-time data. Kibsi’s Vision AI platform steps in as a powerful solution, leveraging the combined strengths of computer vision and AI to transform your loading dock into a hub of optimized efficiency and enhanced safety.

Bridging the Gap Between Technology and Practicality

Kibsi goes beyond simply offering raw data analysis. Our user-friendly platform is designed with the specific needs of loading docks in mind, providing:

- Customizable Solutions: Kibsi understands that every operation has unique challenges. Our platform can be tailored with specific algorithms and functionalities to address your particular needs, whether it’s optimizing dock door scheduling or monitoring worker safety protocols.

- Real-time Monitoring and Alerts: Gain immediate visibility into your loading dock activity. Kibsi utilizes computer vision to provide continuous monitoring, allowing for real-time identification of potential issues. Imagine Kibsi generating an alert if a safety hazard is detected, empowering you to take swift corrective action and prevent accidents.

- Actionable Insights: Kibsi doesn’t just show you data – it translates it into actionable insights. The platform’s AI capabilities analyze the captured data and identify deviations from standard procedures, bottlenecks in workflows, or potential equipment malfunctions. These insights empower you to make data-driven decisions to optimize your processes and ensure smooth operations.

- Seamless Integration: Kibsi integrates seamlessly with your existing WMS (Warehouse Management System), ensuring a smooth transition and minimal disruption to your current workflow. This allows you to leverage the power of Kibsi’s Vision AI without the hassle of a complete system overhaul.

- Scalability: Kibsi’s platform is designed to grow with your business. Whether you’re a small operation or a large-scale logistics hub, Kibsi can accommodate your specific requirements and scale to meet your evolving needs.

The Kibsi Advantage: Real-World Results

Kibsi isn’t just about potential – it delivers real results. Here’s how Kibsi has helped organizations optimize their loading dock operations:

- Reduced Wait Times: One Kibsi customer, a major food distributor, experienced a significant reduction in truck wait times at their loading docks. This translated to faster deliveries, improved customer satisfaction, and substantial cost savings.

- Enhanced Safety: A manufacturing facility using Kibsi reported a dramatic decrease in safety incidents at their loading dock. Kibsi’s real-time monitoring and alerts empowered them to identify and address potential hazards before they could cause accidents.

- Improved Efficiency: A logistics company leveraging Kibsi’s platform saw a significant improvement in loading and unloading efficiency. Kibsi’s actionable insights allowed them to optimize dock door scheduling, eliminate bottlenecks, and streamline their overall workflow.

Getting Started with Kibsi is Easy

Transforming your loading dock operations into a model of efficiency and safety is within reach.

Connect cameras

Map monitoring area

Select trigger(s) & monitor conditions

Select output

Frequently Asked Questions (FAQs)

Quick answers to common questions

AI and computer vision can be used to monitor a wide range of data in industrial processes. This includes:

- Visual data: Presence or absence of objects, object location and orientation, activity tracking of workers or machines.

- Sensor data: Machine temperature, vibration levels, energy consumption (when integrated with existing sensors).

By combining visual and sensor data, Kibsi’s AI platform can provide a holistic view of your processes, enabling you to identify issues that might be missed by traditional monitoring methods.

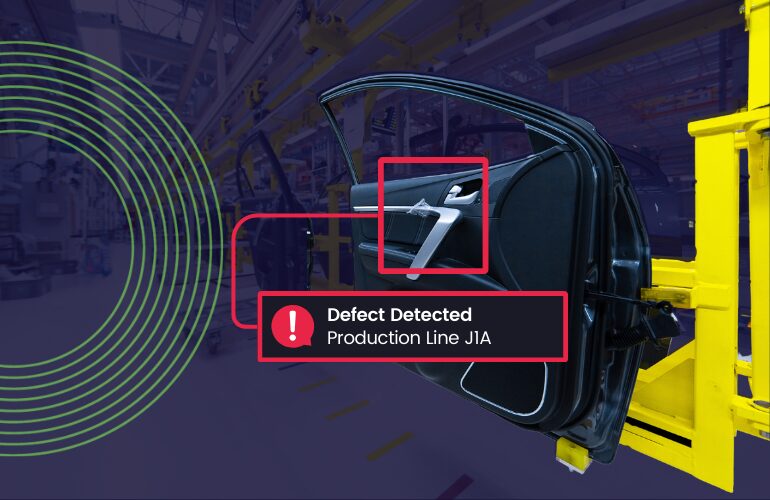

AI and computer vision can significantly enhance quality control by automating visual inspections. Kibsi’s platform can be trained to identify defects in products or deviations from standard procedures, ensuring consistent quality throughout your processes. This reduces the risk of defective products reaching customers and helps maintain a high level of quality control.

Absolutely! AI can analyze data captured by computer vision to identify areas where workflows slow down. For instance, Kibsi might detect congestion points on a conveyor belt or delays in worker activity. This allows you to pinpoint bottlenecks and implement targeted solutions to streamline your processes and improve overall efficiency.

AI and computer vision can be instrumental in enhancing safety in industrial environments. Kibsi’s platform can be configured to monitor for unsafe work practices, such as workers not wearing proper personal protective equipment (PPE). Additionally, it can detect potential equipment malfunctions that could pose safety hazards. By providing real-time alerts for these situations, Kibsi empowers you to take proactive steps to prevent accidents and ensure a safe working environment.

In most cases, Kibsi’s solutions can leverage existing high-definition security cameras already installed in your facilities. This minimizes the need for additional hardware investment. However, depending on your specific needs, Kibsi can also advise on the most suitable camera configurations to optimize the effectiveness of the AI and computer vision technology.

Kibsi’s platform is designed for ease of use and rapid deployment. Our team of experts will handle the installation and configuration process, ensuring a smooth integration with minimal disruption to your operations. Typically, Kibsi’s solutions can be up and running within a short timeframe, allowing you to start reaping the benefits of AI-powered process monitoring quickly.

Kibsi prioritizes data accuracy. Our AI models are rigorously trained on vast datasets relevant to your industry and specific processes. Additionally, Kibsi allows for ongoing customization and fine-tuning of the AI models to ensure they continue to deliver highly accurate results over time.

Kibsi offers flexible pricing plans to suit your specific needs and budget. We can discuss these options in detail during your free consultation. Kibsi’s pricing structure is designed to be transparent and ensure a clear return on investment through improved efficiency, reduced waste, and enhanced safety within your industrial processes.

We’re happy to hear that! Kibsi offers a free consultation to discuss your specific needs and how our Vision AI platform can be customized to address your process monitoring challenges. Contact us today to schedule a consultation or explore a free trial of the Kibsi platform and experience the power of AI and computer vision in optimizing your industrial processes.

How Does Kibsi Work in Your World?

Kibsi is designed to flex to your needs, offering real-time alerts, easy customization, and seamless API integration. Whether it’s tracking freight, monitoring manufacturing or keeping queues moving for concessions, Kibsi turns your video feeds into actionable insights. Intrigued? There’s a lot more to explore.

Hot off the Press: Articles and News

I. Introduction The interest in AI technologies, particularly computer vision (CV), has skyrocketed in recent years. Companies in manufacturing, supply chain, and logistics are eager to explore AI’s potential to transform their operations. According to …

Security cameras have been a fixture in manufacturing plants, warehouses, and distribution centers for years, diligently watching over operations to prevent theft and ensure safety. But as technology has advanced, these once-passive sentinels have evolved …

Introduction In recent years, the manufacturing industry has been undergoing a significant transformation, driven by the rapid advancement of technology and the growing demand for more efficient, sustainable, and human-centric production processes. As we move …

In a recent survey conducted by Kibsi, an astonishing 91% of manufacturing and supply chain professionals expressed their belief that AI will have a notable impact on their industries and, of those, 67% expect that …

When it comes to industries like manufacturing, supply chain, and logistics, computer vision technology is revolutionizing operations by enabling automated systems to interpret and act on visual data. As these industries face increasing demands for …

Is AI a revolution or a fad for traditional industries? Artificial intelligence (AI), particularly computer vision, is creating a stir in manufacturing and logistics. While some leaders are enthusiastic about its potential to streamline operations …

Navigating the ever-expanding web of regulations can feel like running an obstacle course blindfolded. Regulatory compliance across industries – from food and beverage manufacturing to pharmaceuticals and automotive – has become a critical but often …

The specter of automation replacing human jobs has haunted the manufacturing and logistics industries for decades. With the rise of artificial intelligence (AI) and, particularly, computer vision, these concerns have reached a fever pitch. However, …

The countdown to MODEX 2024 is on, and the excitement at Kibsi is palpable! This year, we’re not just attending; we’re showcasing our innovative no-code computer vision platform at Booth #A9911 in Building A. It’s …

The Defect in Defects in Manufacturing Defects in manufacturing can be a costly affair, affecting everything from production efficiency to brand reputation. The ripple effect of undetected defects extends throughout the supply chain, ultimately impacting …