Introduction

In recent years, the manufacturing industry has been undergoing a significant transformation, driven by the rapid advancement of technology and the growing demand for more efficient, sustainable, and human-centric production processes. As we move from the era of Industry 4.0, characterized by automation, IoT, and data analytics, into the new age of Industry 5.0, the focus shifts towards a more collaborative approach between humans and machines, emphasizing sustainability, customization, and social responsibility.

At the forefront of this transformation is computer vision, a powerful technology that enables organizations to harness the full potential of their video data. By integrating computer vision into existing systems and processes, manufacturers can gain real-time insights, optimize operations, and achieve their Industry 5.0 goals. In this article, we’ll explore the role of computer vision in the Industry 5.0 era and how technology like Kibsi is empowers organizations to see their business in a whole new way.

The Evolution of Manufacturing: From Industry 4.0 to Industry 5.0

Industry 4.0 laid the groundwork for the digital transformation of manufacturing, introducing technologies such as the Internet of Things (IoT), automation, and data analytics. These innovations have revolutionized the way products are designed, produced, and distributed, enabling manufacturers to optimize processes, reduce costs, and improve quality. However, as the world faces new challenges and evolving customer demands, the manufacturing industry must adapt once again. Industry 5.0 builds upon the foundations of Industry 4.0, placing a greater emphasis on human-machine collaboration, sustainability, and socially responsible production. Some of the key characteristics of Industry 5.0 include:

- Human-machine collaboration: Leverage the creativity and problem-solving skills of humans alongside the efficiency and precision of machines.

- Customization and personalization: Enable the production of customized products on a mass scale to meet individual customer needs.

- Flexible production: Adopt agile manufacturing systems that can quickly adapt to changing market demands and unforeseen disruptions.

- Sustainability: Prioritize eco-friendly practices, waste reduction, and energy efficiency to minimize environmental impact.

- Data-driven decision-making: Utilize data and analytics to inform strategic decisions, optimize processes, and drive continuous improvement.

- Skill enhancement: Foster a workforce with a unique blend of technical skills, creativity, and adaptability to thrive in the Industry 5.0 era.

The Power of Computer Vision in Industry 5.0

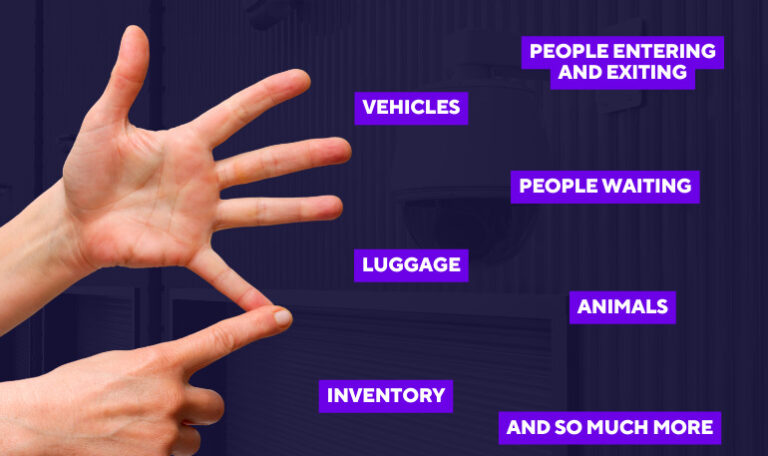

As manufacturers navigate the transition to Industry 5.0, computer vision emerges as a critical technology that aligns perfectly with the principles of this new era. By leveraging existing video cameras to capture and analyze real-time data, computer vision enables organizations to gain unprecedented insights into their operations, empowering them to make data-driven decisions and drive continuous improvement. Embrace the key benefits of computer vision in the context of Industry 5.0:

- Real-time monitoring and data collection: Monitor production processes, equipment performance, and worker safety in real-time, providing a wealth of actionable data.

- Improved process efficiency and quality control: Detect defects, anomalies, and deviations from standard operating procedures to optimize processes and maintain consistent quality.

- Enhanced safety and compliance: Identify potential safety hazards, monitor compliance with safety protocols, and alert relevant personnel to take corrective action.

- Optimized resource utilization and waste reduction: Track inventory levels, monitor equipment usage, and identify inefficiencies to optimize resource allocation and minimize waste.

Real-World Applications of Computer Vision in Manufacturing

The potential applications of computer vision in manufacturing are vast and diverse, spanning across various industries and use cases. Here are just a few of the most compelling examples:

- Defect and anomaly detection: Automatically identify defects in products or components, reducing the need for manual inspection and minimizing the risk of quality issues reaching customers.

- Label detection and quality control: Verify the accuracy and integrity of product labels to ensure that products are correctly identified and tracked throughout the supply chain.

- Safety alerts and compliance monitoring: Detect when workers are not wearing required personal protective equipment (PPE) or when they enter hazardous areas, triggering real-time alerts to prevent accidents and injuries.

- Volumetric space optimization: Analyze the utilization of storage space and identify opportunities for optimization to maximize the efficiency of warehouses and distribution centers.

- Misplaced item detection: Track the location of tools, equipment, and materials, alerting workers when items are misplaced or missing, reducing downtime and improving productivity.

- Productivity tracking and shift variance analysis: Monitor worker performance and identify variations in productivity across different shifts or production lines to provide valuable insights for process improvement and resource allocation.

Kibsi: Empowering Industry 5.0 with No-Code Computer Vision

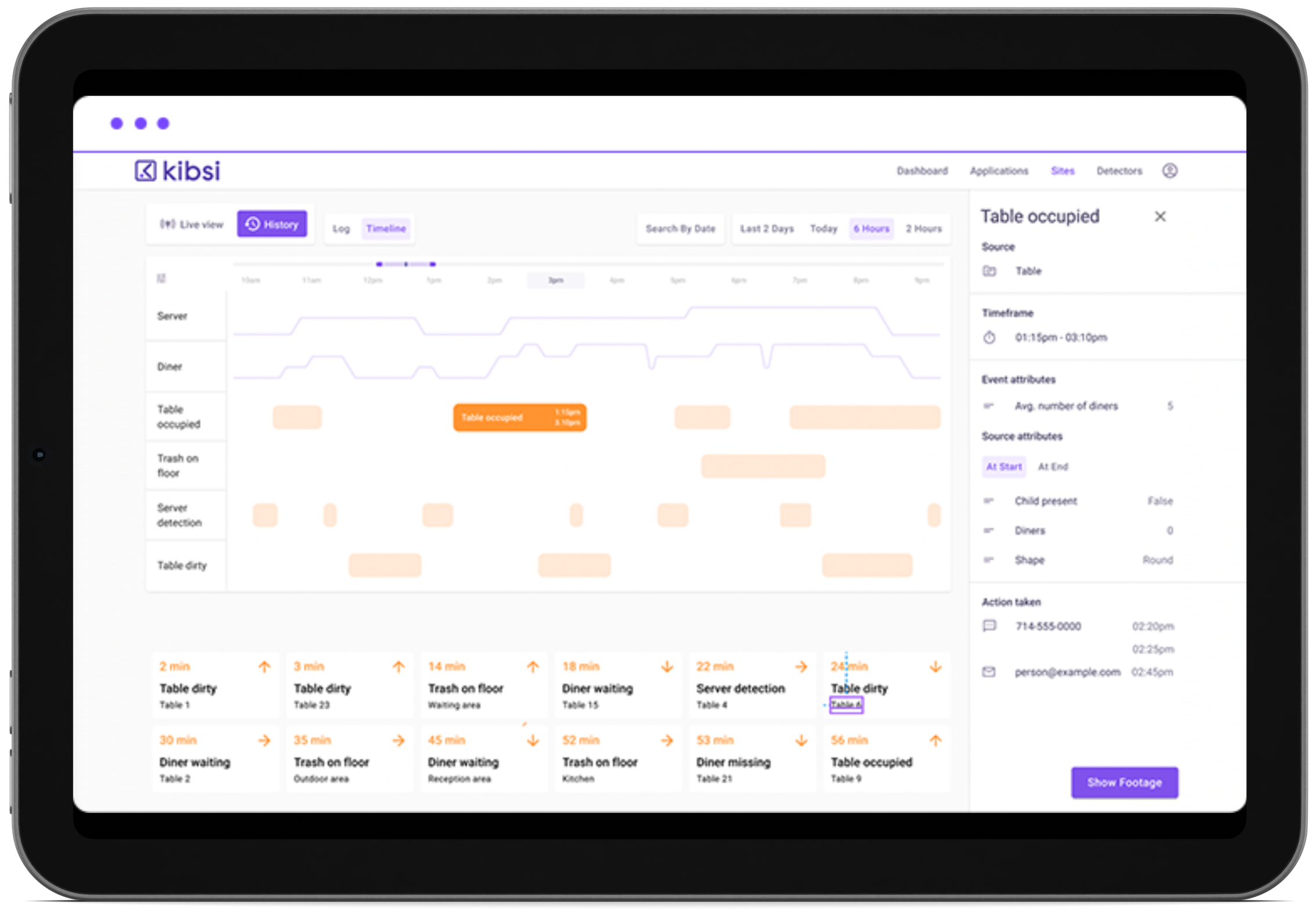

Kibsi is a powerful, user-friendly platform that enables organizations to harness the power of computer vision without the need for extensive coding or technical expertise. With its intuitive, no-code interface and pre-built computer vision models, Kibsi makes it easy for manufacturers to integrate computer vision into their existing systems and processes, unlocking the full potential of their video data. Take advantage of the key features and benefits of Kibsi:

- No-code, intuitive interface: Create custom computer vision applications without writing a single line of code using Kibsi’s drag-and-drop interface.

- Pre-built and customizable models: Access a wide range of pre-built computer vision models tailored to specific manufacturing use cases, and create custom models to meet unique requirements.

- Real-time analytics and alerts: Access real-time insights and receive instant alerts when critical events or anomalies are detected, enabling proactive measures and minimizing downtime.

- Seamless integration: Integrate Kibsi seamlessly with existing video cameras and systems, making it easy to deploy and scale computer vision applications across multiple sites and production lines.

- Scalability and flexibility: Adapt to new challenges and opportunities with Kibsi’s flexible architecture, allowing for easy scaling as organizations grow and their needs evolve.

Next Steps

As the manufacturing industry embraces the principles of Industry 5.0, computer vision will play an increasingly crucial role in enabling organizations to optimize processes, enhance safety, and drive sustainable growth. By harnessing the power of video data and real-time insights, manufacturers can create a more collaborative, efficient, and socially responsible production environment. Kibsi empowers organizations to unlock the full potential of computer vision, providing a user-friendly, no-code platform that makes it easy to integrate this transformative technology into existing systems and processes.

With Kibsi, manufacturers can gain a competitive edge in the Industry 5.0 era, driving innovation, improving customer satisfaction, and achieving their sustainability goals. Experience the benefits of no-code computer vision today – contact us for a demo of Kibsi and discover how it can help you see your business in a whole new way and thrive in the exciting future of manufacturing.