Introduction

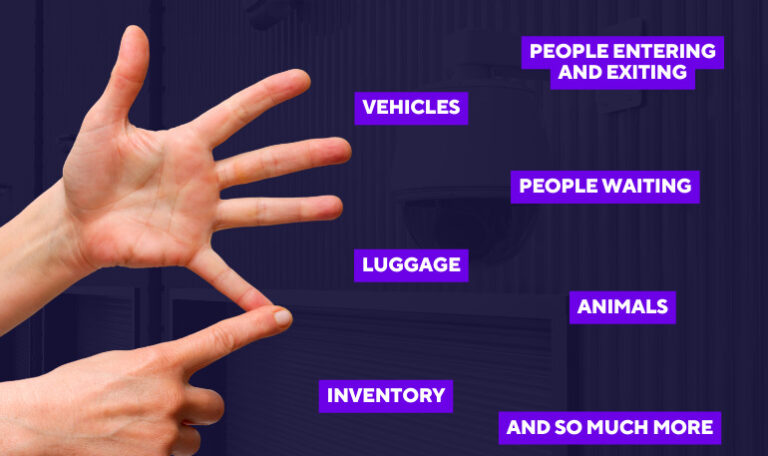

In the rapidly evolving world of manufacturing, computer vision technology is proving to be a game-changer. With its ability to process and analyze video in real time, computer vision offers unprecedented opportunities to enhance safety, increase efficiency, and improve quality. This post explores five key use cases for video-based computer vision in manufacturing, showcasing how this innovative technology is driving value and revolutionizing operations.

1. Personal Protective Equipment (PPE) Monitoring

In a world where up to 89% of workers were found non-compliant with PPE protocols in previous years, ensuring that all personnel adheres to safety guidelines is crucial1. Computer vision technology can continuously monitor the manufacturing floor, verifying that all workers are wearing the correct PPE. Through real-time alerts, it can immediately notify supervisors of any violations, facilitating swift corrective action. This proactive approach not only enhances worker safety but also fosters a culture of compliance, reducing the risk of injury and potential legal liability.

2. Forklift Safety Alerts

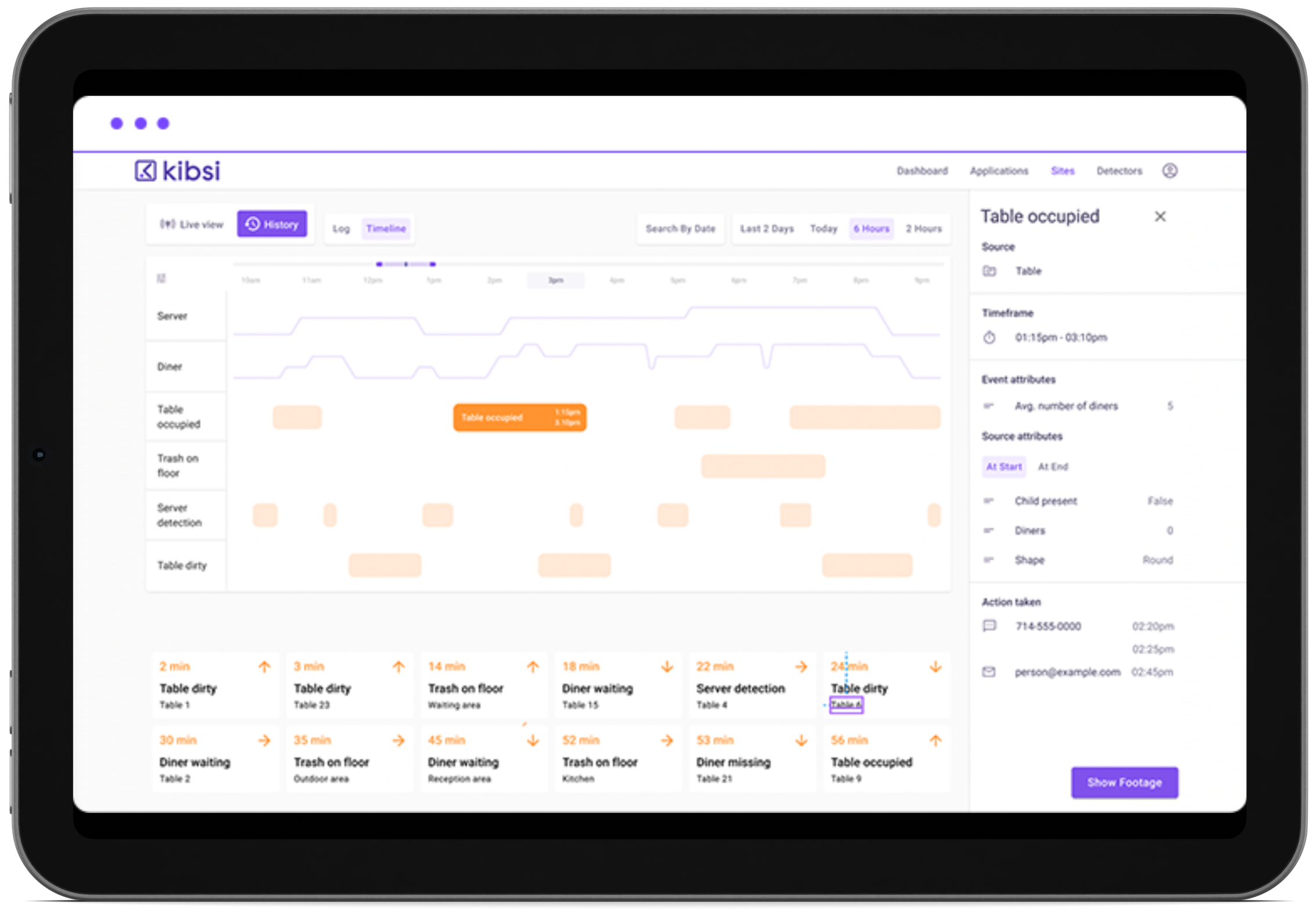

In 2021, forklifts were the source of 70 work-related deaths and 7,290 nonfatal injuries involving days away from work2. This highlights the importance of maintaining a safe distance between workers and these powerful machines. Using video-based computer vision, a system like Kibsi can generate safety alerts when people come too close to operating forklifts or when forklifts venture outside designated areas. By ensuring proper adherence to safety protocols, such systems can significantly reduce the risk of accidents and improve overall operational safety.

3. Defect Detection

Quality control is a critical aspect of manufacturing, and with true quality-related costs amounting to as high as 15-20% of sales revenue, the stakes are high3. Computer vision provides an effective solution to this challenge, with its ability to detect defects and irregularities that might be missed by the human eye. Real-time video analysis can identify flaws in products as they move down the assembly line, allowing for immediate correction and significantly reducing the risk of substandard products reaching the market.

4. Worker/Machine Interactions

With 84% of all nonfatal injuries at work in the US being caused by overexertion, slips, trips, and contact with objects and equipment, ensuring safe worker-machine interactions is paramount4. Video-based computer vision can monitor these interactions, alerting supervisors when workers come too close to dangerous equipment or engage in unsafe behaviors. This real-time monitoring and alert system helps prevent accidents, ensuring a safer workplace and minimizing downtime due to injuries.

5. Distribution Solutions

Ensuring the correct and quality distribution of products is a vital part of manufacturing. With the use of computer vision, manufacturers can validate labels, package contents, and other shipping requirements in real time. This not only guarantees the delivery of the right products to the right destinations but also reduces the risk of costly mistakes and customer dissatisfaction.

Conclusion

As these use cases illustrate, computer vision technology is a powerful tool for enhancing safety, efficiency, and quality in manufacturing. Despite significant progress in workplace safety in recent decades, with workplace deaths in the United States down by more than 60% and the workplace injury and illness rate dropping by about 74% in a 47-year period5 6, there is still room for improvement. With the advent of systems like Kibsi, manufacturers can leverage the power of video-based computer vision to transform their operations, providing them with actionable insights and alerts in real time.

Interested in learning more about the potential of computer vision in manufacturing? Download our Computer Vision for Manufacturing eBook to dive deeper into the topic. In it, we explore a range of other applications and delve into case studies of how companies are already reaping the benefits of this transformative technology.

Future Prospects

Looking ahead, we can expect the role of computer vision in manufacturing to continue to grow. As the technology matures and more use cases are discovered, the industry will continue to innovate, unlocking new ways to improve safety, efficiency, and quality.

Moreover, as advanced analytics capabilities are integrated with computer vision, the technology’s potential will increase even further. For instance, predictive analytics can be used alongside video-based insights to anticipate potential equipment failures or safety risks before they occur, enabling proactive measures to be taken.

Final Thoughts

In a world where workplace accidents continue to cause significant harm and cost, with an estimated $250 billion each year spent on workplace injuries and illnesses in the US1, and with 15% of workplace injuries occurring in manufacturing jobs2, the value of computer vision technology in enhancing safety and efficiency cannot be overstated.

As we look to the future, it’s clear that the use of video-based computer vision in manufacturing is not just a passing trend but a key driver of industrial evolution. The potential applications for this technology are vast, extending beyond safety to improve quality control, enhance distribution, and drive operational efficiency. If you’re interested in learning more about how computer vision can transform your manufacturing operations, download our Computer Vision for Manufacturing eBook today. Dive deeper into the world of computer vision and discover the untapped potential that this transformative technology holds for your business.