The Defect in Defects in Manufacturing

Defects in manufacturing can be a costly affair, affecting everything from production efficiency to brand reputation. The ripple effect of undetected defects extends throughout the supply chain, ultimately impacting end-users and tarnishing brand images. In this context, the quest for more effective defect detection methods has become critical for manufacturers aiming to uphold high-quality standards.

The Problem of Defects in Manufacturing

Defects in the manufacturing process can be a thorn in the side for businesses, impacting not just the bottom line but also customer trust and brand reputation. Let’s break down the impact:

- Cost Implications: Every defective product that slips through the cracks can mean wasted materials, labor, and operational time, driving up production costs.

- Efficiency Roadblocks: Defects can cause production bottlenecks, reducing the overall efficiency of the manufacturing process.

- Reputation Risks: In today’s digital age, a single defective product can lead to negative reviews and social media backlash, affecting brand reputation and customer loyalty.

Current Solutions for Defect Detection

Traditional defect detection methods, while once cutting-edge, now face challenges that can significantly hinder their effectiveness in today’s fast-paced manufacturing world. Let’s dive into the specifics:

Manual Inspections: Although thorough, manual checks are notoriously slow and require a lot of manpower. They’re prone to mistakes since even the most diligent worker can’t catch every flaw. Plus, when you’re producing goods on a large scale, inspecting each item by hand just isn’t feasible.

Traditional Automated Systems: These systems, designed to speed up the defect detection process, are often hamstrung by their inability to adapt. They work well for what they’re programmed to do, but throw in a new product line or a slight change in specifications, and they can’t keep up without costly and time-consuming updates. Setting them up is expensive, and they need regular maintenance, which means production has to pause, leading to further delays and costs.

Given these constraints, it’s clear the industry is in dire need of more sophisticated solutions. Here’s why:

- Real-Time Feedback is a Must: The biggest shortfall of both manual inspections and traditional automated systems is their delay in identifying defects. Immediate detection is vital for reducing waste and saving costs, allowing for on-the-fly adjustments before products move too far down the line.

- Flexibility is Non-Negotiable: The manufacturing world moves quickly, with frequent updates to product designs and materials. Defect detection systems that can’t easily adjust to these changes will quickly become obsolete, holding back production and innovation.

- Data is Gold: Current methods often overlook the power of data analysis. The ability to integrate and analyze data from the manufacturing process can lead to significant improvements, predicting potential issues before they arise and offering insights for future developments.

In essence, the search for advanced defect detection methods is not just about solving current problems—it’s about anticipating future challenges and staying ahead in a competitive market. Manufacturers are increasingly looking for dynamic, data-driven solutions that can adapt to their evolving needs, minimize downtime, and turn the tide from reactive to proactive quality control. This is where the potential for significant advancements lies, with technology playing a key role in shaping the future of manufacturing.

Exploring Computer Vision in Manufacturing

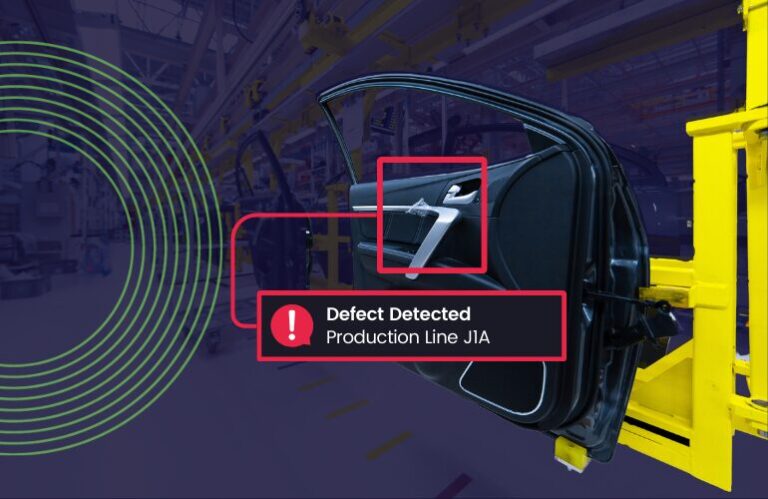

Computer vision is a transformative force in the manufacturing sector, utilizing advanced technology to enable machines to interpret and understand visual information from their environment. This branch of artificial intelligence has witnessed remarkable advancements, positioning it as a critical tool for a variety of applications, notably in defect detection. Through the integration of machine learning algorithms, computer vision systems capture and analyze images or video footage, efficiently identifying product irregularities or defects. This approach not only exemplifies the practical application of AI but also showcases how computer vision is becoming a valuable entry point for AI in the industry, generating actionable data while simultaneously delivering a return on investment (ROI).

The Revolutionary Impact of Computer Vision on Defect Detection

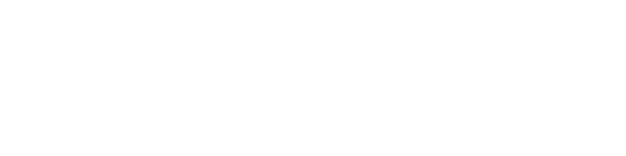

The deployment of computer vision for defect detection represents a major advancement over traditional inspection methods. Leveraging the power of artificial intelligence and machine learning, these systems automate the analysis of visual data, achieving unmatched accuracy and efficiency. Unlike the exhaustive and error-prone manual inspections, computer vision operates around the clock, providing real-time alerts and insights into potential defects. Its superior flexibility allows it to adapt to diverse manufacturing settings and identify a broader spectrum of defects, highlighting the potential of visual intelligence in modern quality control processes.

Integrating Kibsi into the Computer Vision Ecosystem

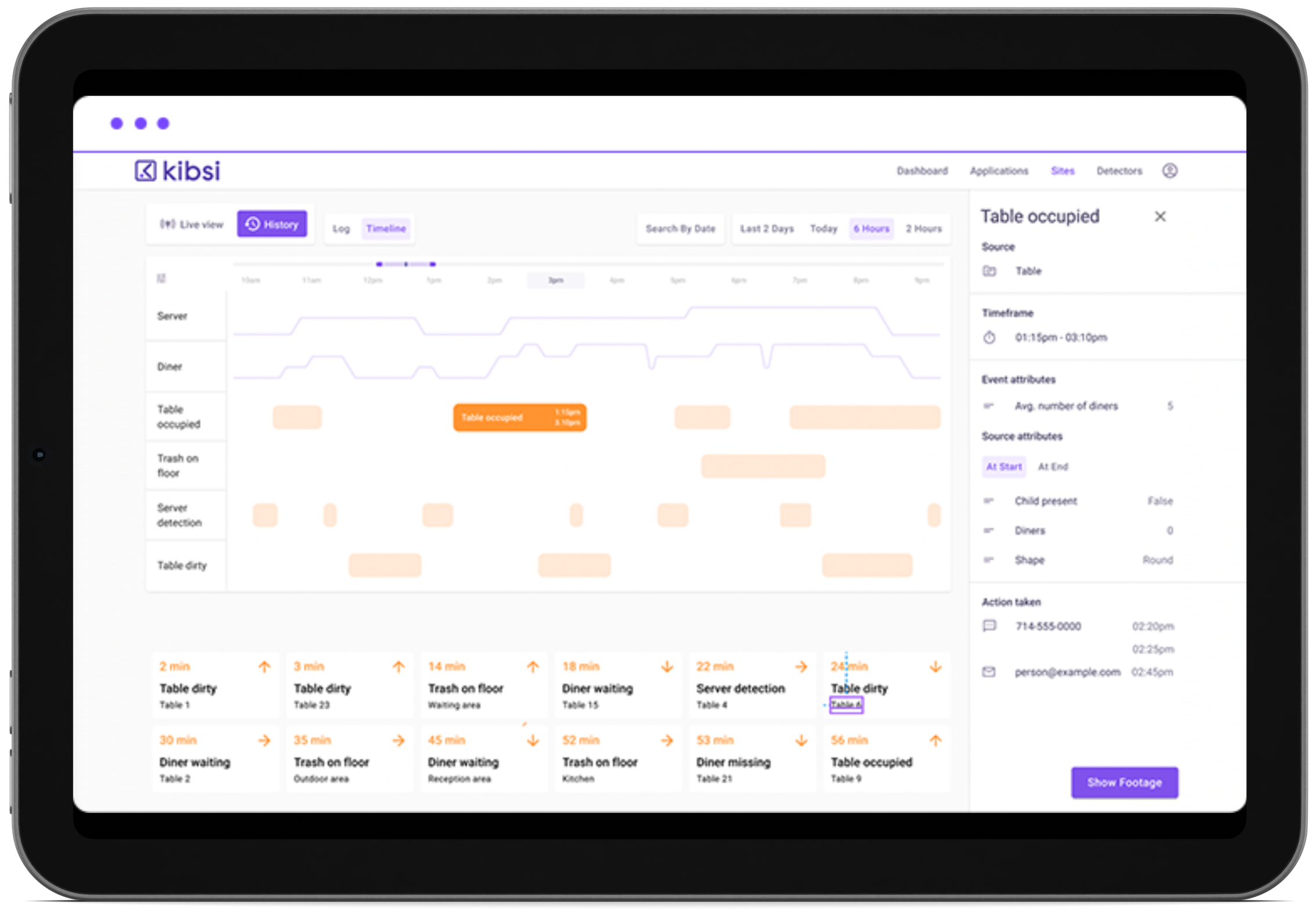

Here at Kibsi, we pride ourselves on being a pioneering no-code video intelligence platform that bridges the gap between your existing camera systems and the advanced capabilities of computer vision. We enable you to leverage your current setup to develop custom computer vision applications focused on elevating defect detection. This seamless integration not only enhances the efficiency of your quality control processes but also simplifies the journey toward adopting AI and machine learning technologies. At Kibsi, we’re dedicated to unlocking the power of visual intelligence for your business, providing an accessible route to embedding sophisticated AI solutions into your operations and thereby transforming the landscape of manufacturing quality control.

Value Delivered to Manufacturers by Computer Vision

In the competitive landscape of door manufacturing, efficiency, quality, and customer satisfaction are paramount. Consider a door manufacturing company that produces 100,000 doors annually. With a current defect rate of 5%, this equates to 5,000 defective doors per year. However, the financial impact of these defects, particularly through warranty claims, is substantial.

- Current Financial Impact: The company processes 10 door warranty claims daily, with each claim costing $150. This results in an annual expenditure of $1,277,500 on warranty claims alone. Including returns and the cost of scrapping defective products, the total financial burden due to defects significantly exceeds this figure.

Integrating computer vision into the manufacturing process offers a means for drastically reducing these costs. Here’s the revised breakdown of benefits:

- Early Identification of Defect-Causing Scenarios: By utilizing computer vision, the company can detect potential defects during the production process in real-time. This proactive approach allows for immediate adjustments, significantly lowering the defect rate. Assuming that computer vision could reduce the defect rate by 50%, this would not only enhance product quality but also lead to a direct reduction in warranty claims. Consequently, the company could potentially save approximately $273,750 annually on warranty claims alone.

- Source Tracking for Defects: The precision tracking enabled by computer vision helps identify the origins of defects, whether they’re specific production lines or material batches. This targeted insight allows for quicker, more effective corrective actions, reducing downtime and minimizing the labor involved in troubleshooting. Enhanced efficiency in addressing the root causes of defects can further reduce indirect costs, such as those associated with production delays and additional inspection requirements.

- Reduction in Rework, Returns, and Warranty Claims: With a more accurate and efficient defect detection system, the company is better equipped to ensure that only doors meeting the highest quality standards reach the customer. This reduction in defects directly translates to fewer warranty claims and returns.

By adopting computer vision for defect detection, the door manufacturer not only aims to halve their current defect-related expenses but also to significantly enhance operational efficiency and product quality. This strategic move not only saves costs but also strengthens the brand’s reputation in the market, ultimately leading to higher customer satisfaction and loyalty.

With the precise, real-time capabilities of computer vision, the door manufacturer sets a new standard in manufacturing excellence, proving that the right technological investment can yield substantial returns.

Kibsi’s Unique Contributions to Defect Detection

What sets Kibsi apart in the computer vision landscape is our commitment to offering real-time monitoring capabilities and delivering actionable insights. Our platform’s adaptability in model selection and the ability to create custom applications are designed to meet the unique needs of different manufacturing environments. With Kibsi, every manufacturer can find a tailored solution that aligns perfectly with their operational requirements. Furthermore, our APIs ensure easy integration with other systems, promoting a comprehensive strategy for operational excellence.

The role of computer vision in revolutionizing defect detection in manufacturing cannot be overstated. With Kibsi at the forefront, we’re opening doors for manufacturers to significantly upgrade their quality control processes, guaranteeing that products adhere to the highest standards of quality. If you’re eager to discover how computer vision can benefit your manufacturing operations, we invite you to explore Kibsi. Our tailored demonstrations offer a peek into the future of manufacturing quality control, showcasing how our technology can be a game-changer for your business.