As technology advances, warehouse operators are finding new and innovative ways to leverage computer vision and AI to improve productivity and safety in their facilities. Computer vision can be used for a variety of tasks, such as forklift tracking, PPE compliance, critical area monitoring, inventory management, and more! By adding computer vision and AI capabilities to existing security cameras, warehouses can stay ahead of the curve and keep up with the latest trends in logistics and supply chain management.

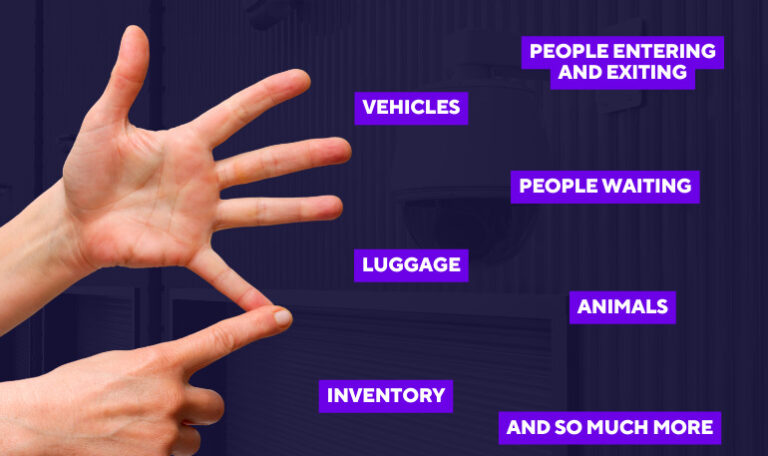

See Kibsi in action!

What is computer vision?

Computer vision is a field of artificial intelligence that teaches computers how to interpret and understand digital images. This can be done in a number of ways, but the most common method is through the use of deep learning algorithms. Deep learning is a type of machine learning that involves feeding a computer data that is structured in layers, to teach it to recognize patterns.

How can computer vision be used in warehouses?

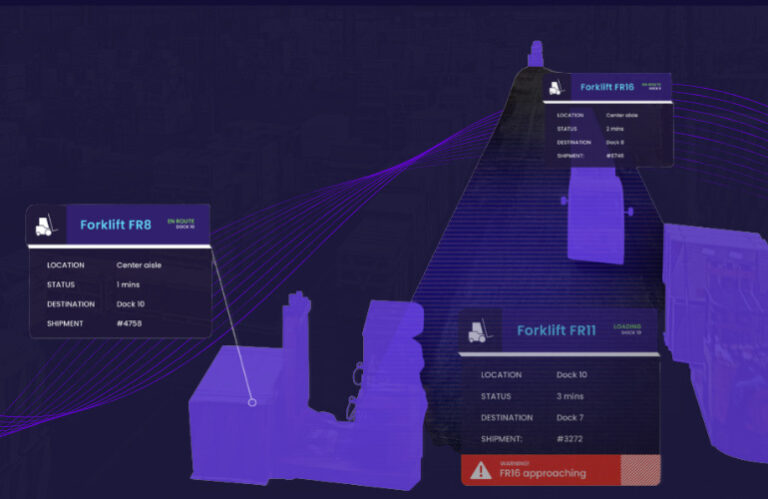

There are several ways in which computer vision can be used in warehouses. One way is through the use of robots, which can be equipped with cameras to complete tasks such as identifying and picking up items. Another way is through powering up existing security cameras with computer vision capabilities that can be used for tasks like counting inventory, tracking packages, and ensuring products are being stored correctly. Computer vision can also be used to monitor employee productivity and safety.

What are the benefits of using computer vision in warehouses?

There are several benefits to using computer vision in warehouses. Here are a few examples of how warehouse operators are leveraging computer vision and AI today:

- Improved accuracy & efficiency: One of the primary benefits of using computer vision in warehouses is that it can help to improve accuracy and efficiency by automating tasks that would otherwise need to be done manually, such as speeding up the picking process. Picking is the process of selecting the correct items from a warehouse shelf and packing them into boxes for shipment. Computer vision can be used to automatically identify and locate items that need to be picked, which can help to reduce the time it takes to complete an order and chance of human error.

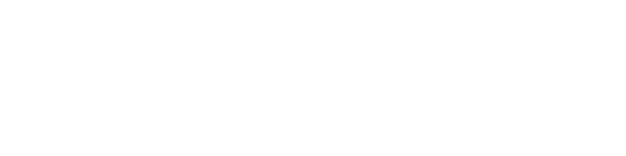

- Increased Safety: Computer vision can also help to improve safety by identifying potential hazards before they cause an accident and reducing the need for employees to work near dangerous machinery. Warehouse workers are often required to climb ladders or operate forklifts to reach items that need to be picked. This can be dangerous, and there is always the potential for accidents. By using computer vision to automatically identify and locate items, workers can stay safely on the ground and avoid potential accidents.

- Better Inventory Management: Another benefit of using computer vision in warehouses is that it can help with inventory management. To ensure that items are always available when needed, warehouse managers need to have a good understanding of what is in stock and where it is located. Computer vision can be used to automatically track inventory levels and locations, which can help managers make better decisions about stocking and reordering.

- Reduced Costs: Finally, computer vision and AI can also help to reduce costs in warehouses by automating routine tasks like the picking process. Automated picking can lead to reduced human error, which can help to save money by reducing the need for returns or replacements and improve customer satisfaction by ensuring that orders are filled correctly and in a timely manner.

What are some challenges associated with using computer vision in warehouses?

One challenge associated with using computer vision in warehouses is that the technology is still relatively new and therefore there may be some bugs or glitches that need to be ironed out. Additionally, because computer vision relies on artificial intelligence, it requires a significant amount of data to function properly. This data must be carefully labeled and structured for the algorithms to learn from it effectively. Finally, another challenge is that computers still lack the ability to see and interpret the world in the same way that humans do. This means that they may not be able to identify certain objects or situations as effectively as humans can. That’s where a computer vision platform like Kibsi comes in. Kibsi allows any user to build and launch a computer vision solution in minutes, without the need to train a model.

There are many ways savvy warehouse operators are levering their existing camera assets and computer vision to increase efficiency, improve productivity, and enhance safety. Let’s chat to see how your warehouse can take advantage of computer vision to drive revenue.