In a recent survey conducted by Kibsi, an astonishing 91% of manufacturing and supply chain professionals expressed their belief that AI will have a notable impact on their industries and, of those, 67% expect that impact to be transformative. This statistic underscores the growing recognition of the potential for computer vision technology. As companies grapple with the challenges of optimizing operations, ensuring worker safety, and maintaining product quality, they are increasingly turning to computer vision as a powerful solution.

At Kibsi, we have witnessed firsthand the excitement and anticipation surrounding computer vision in the manufacturing and supply chain sectors. Our survey, which gathered insights from industry professionals across various roles and company sizes, reveals a clear consensus: computer vision is rapidly emerging as a game-changer, offering unparalleled opportunities to enhance efficiency, safety, and quality. In this article, we will explore the key reasons behind this growing interest.

The Allure of Computer Vision: Key Drivers of Adoption

1. Enhanced Safety

Safety is a paramount concern for manufacturing and supply chain companies, and our survey data reflects this priority. An overwhelming majority of respondents rated forklift and equipment safety as a high-value application of computer vision. This comes as no surprise, given the potential for accidents and injuries in fast-paced, machinery-intensive environments.

Computer vision technology enables real-time monitoring of equipment, processes, and employee behavior, allowing companies to prevent accidents and ensure compliance proactively with safety protocols. At Kibsi, we offer advanced capabilities and pre-built solutions in areas like forklift safety, PPE detection, and anomaly detection. Our platform can detect and alert operators to unsafe practices, such as speeding or operating without proper safety gear, thereby significantly reducing the risk of accidents.

2. Improved Quality Control

Product quality is another critical factor driving the adoption of computer vision in manufacturing and supply chain. Our survey findings highlight the challenges companies face with manual inspection methods, which can be time-consuming, error-prone, and inconsistent. In fact, 89% of respondents identified product quality inspection as a high-value use case for computer vision.

By automating and streamlining quality control processes, computer vision technology enables greater accuracy, consistency, and early defect detection. Kibsi’s platform offers powerful capabilities in product inspection, defect identification, and quality assurance. Our algorithms can detect even the subtlest anomalies, ensuring that only products meeting the highest quality standards make it through the production line. This not only reduces waste and rework but also enhances customer satisfaction and brand reputation.

3. Increased Efficiency and Productivity

In today’s competitive landscape, manufacturing and supply chain companies are constantly seeking ways to optimize operations and boost productivity. Our survey data reflects this focus, with a significant majority of respondents (76%) highlighting process monitoring and optimization as a key area where computer vision can deliver value.

By automating tasks, streamlining workflows, and providing real-time insights, computer vision technology helps eliminate bottlenecks and improve overall efficiency. Kibsi’s platform offers a range of capabilities designed to enhance productivity, such as process optimization, inventory management, and logistics monitoring. For example, our computer vision algorithms can track the movement of goods through the supply chain, identifying delays or inefficiencies and suggesting optimized routes or storage strategies.

Real-world results speak to the impact of computer vision on efficiency. One of our customers, a global logistics company, calculates that they will save an estimated 9,000 worker hours annually by automating processes like scanning labels on incoming shipments. Another customer, a leading manufacturer, experienced a significant reduction in production micro-stoppages by leveraging Kibsi’s platform to detect and address issues on the assembly line proactively.

4. Data-Driven Decision Making

As manufacturing and supply chain operations become increasingly complex, the role of data analytics in driving informed decision-making cannot be overstated. Our survey reveals a growing recognition of this importance, with many respondents expressing interest in leveraging computer vision to generate actionable insights.

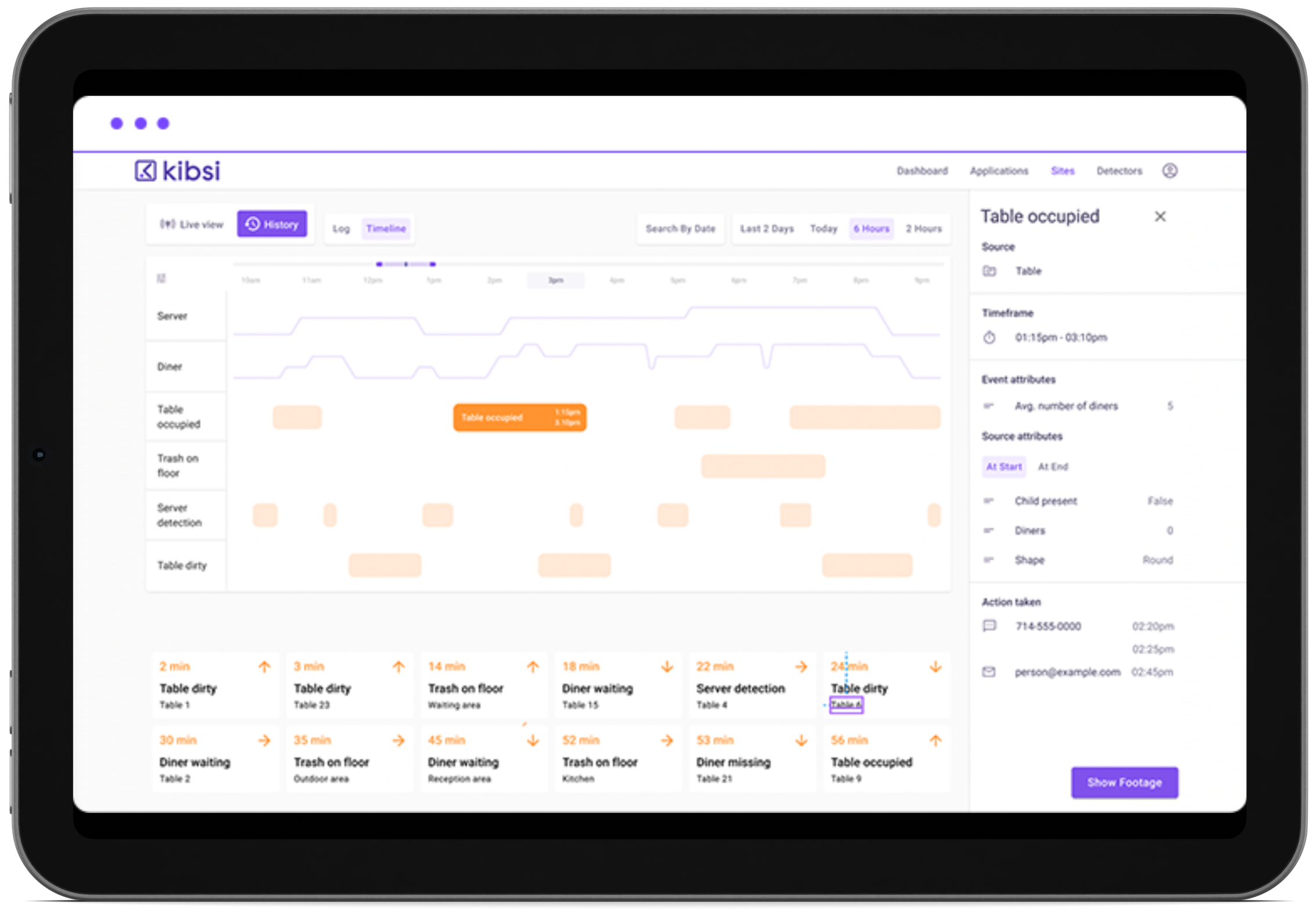

Computer vision technology generates a wealth of valuable data that provides a granular view of operations. By analyzing this data, businesses can identify patterns, trends, and improvement opportunities that may not be apparent through manual observation alone. Kibsi’s platform includes powerful data visualization and reporting tools that empower businesses to extract meaningful insights from their operations.

For instance, our heatmap generation capabilities allow companies to visualize facility utilization and movement patterns, helping them optimize layouts and resource allocation. Our real-time dashboards provide instant visibility into key performance indicators, enabling managers to make data-driven decisions on the fly. By leveraging the data generated by computer vision, companies can continuously refine their processes and stay ahead of the curve.

Kibsi: Enabling the Computer Vision Revolution

At Kibsi, we are committed to enabling the computer vision revolution in manufacturing and supply chain. Our comprehensive platform offers a wide range of solutions that cater to the diverse needs of businesses in these industries. From safety and quality control to efficiency and data analytics, Kibsi has you covered.

One of the key strengths of our platform is its accessibility and scalability. Whether you are a small manufacturer just starting your digital transformation journey or a large-scale logistics operation with complex requirements, Kibsi can adapt to your needs. Our modular architecture allows you to start small and scale up as your business grows, ensuring that our solutions remain relevant and effective over time.

Another crucial aspect of Kibsi’s platform is its ease of implementation. We understand that adopting new technology can be daunting, which is why we have designed our platform with simplicity in mind. Our low-code approach means that even users without extensive technical expertise can quickly set up and configure our solutions. We also offer seamless integration with existing systems, minimizing disruption to your current workflows.

Realizing the Vision: Success Stories and Future Potential

The true measure of computer vision’s impact lies in the tangible results achieved by companies that have embraced this technology. At Kibsi, we have had the privilege of working with a diverse range of customers who have successfully implemented our platform to drive meaningful improvements in their operations.

One such success story comes from a Fortune 500 manufacturer of construction materials. By using Kibsi to spot abnormalities on the assembly line, they were able to prevent costly production micro-stoppages and enhance overall efficiency. Another customer, a major U.S. distributor, leveraged our platform to verify products and quantities during loading and unloading, resulting in improved accuracy, enhanced customer experience, and clean invoicing.

These success stories are just the tip of the iceberg when it comes to the potential of computer vision in manufacturing and supply chain. As the technology continues to evolve, we can expect to see even more innovative applications emerge. For instance, the integration of computer vision with other cutting-edge technologies like artificial intelligence and machine learning could enable predictive maintenance, allowing companies to anticipate and prevent equipment failures before they occur.

Looking ahead, the future of computer vision in these industries is incredibly exciting. As more companies recognize the value of this technology and invest in its adoption, we can expect to see a widespread transformation of manufacturing and supply chain operations. From fully automated quality control systems to intelligent logistics networks that optimize routes in real-time, the possibilities are endless.

At Kibsi, we are committed to staying at the forefront of this evolution. We are constantly innovating and refining our platform to meet the changing needs of our customers and to push the boundaries of what is possible with computer vision. Our team of experts is dedicated to helping companies navigate the complexities of this technology and unlock its full potential.

Conclusion

The manufacturing and supply chain industries stand at the cusp of a technological revolution, and computer vision is leading the charge. As we have seen through our survey data and real-world success stories, the allure of computer vision lies in its ability to enhance safety, improve quality control, increase efficiency, and enable data-driven decision making.

At Kibsi, we are proud to be a leading platform that empowers companies to leverage the power of computer vision and achieve their operational goals. Our comprehensive solutions, accessibility, scalability, and ease of implementation make us the ideal partner for businesses looking to embark on their computer vision journey.

If you are ready to transform your manufacturing or supply chain operations and unlock the full potential of computer vision, we invite you to explore Kibsi further. Our team of experts is ready to guide you through the process and help you realize the vision of a safer, more efficient, and data-driven future.

The future belongs to those who embrace innovation and harness the power of technology. With Kibsi by your side, you can be at the forefront of the computer vision revolution and set your business up for success in the years to come. Let us help you turn your vision into reality. Contact us to learn more about how Kibsi could help your organization.