Gone are the days of frustrating manual monitoring and data collection in manufacturing. Modern factories are embracing Industry 4.0, and one of the most powerful tools (and potentially easiest to implement) in their arsenal is computer vision. Computer vision can play a crucial role in automating processes and improving overall production efficiency. It’s no surprise that many manufacturers are investing in computer vision technology to stay competitive in today’s market.

We’ve gathered some of our favorite examples and use cases for how computer vision will be used to improve and transform manufacturing in 2023 and beyond. Download our ebook for a deeper dive into how computer vision is transforming manufacturing.

Safety

With over 400,000 injuries in manufacturing in 2019, it’s not surprising that factories are eagerly looking for new strategies to keep workers safe. Computer vision is proving to be one of the most powerful and consistent strategies for accomplishing this goal helping solve a range of use cases from PPE compliance to preventing workers from entering dangerous zones.

Quality Control

Computer vision is becoming an increasingly important tool for quality control in manufacturing. By tracking the position and orientation of objects as they move through the manufacturing process, factories can use computer vision to identify defects and problems that could affect the quality of the final product and more.

Process Optimization

By tracking the position and orientation of objects as they move through the manufacturing process, factories can use computer vision to identify defects and problems that could affect the quality of the final product and prevent micro stoppages.

Predictive Maintenance

Predictive maintenance in manufacturing gets significant attention – and rightly so as it can ultimately save organizations substantial money. By tracking the position and orientation of objects, factories can use computer vision to predict when parts are going to wear out and need to be replaced. This allows factories to plan for replacements in advance, preventing any unexpected downtime in the production process.

Worker Health

For some factories, worker posture and physical tasks – particularly repetitive tasks – are a double-edged sword. While those tasks are critical, it’s equally important that workers perform them safely to avoid injuries and health issues. By constantly monitoring posture, the company can proactively address any ergonomic concerns and create a safer work environment through training and support tools.

Energy Management

Computer vision is also being used in manufacturing to save energy. By monitoring equipment and identifying any that are not in use, factories can turn off unused equipment and reduce their energy consumption.

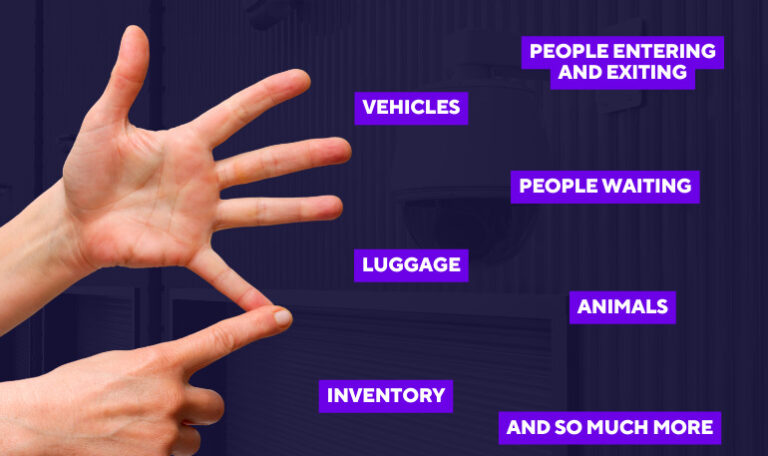

Inventory Management

Computer vision can be used to track inventory levels in factories automatically. This information can then be used to optimize production schedules and avoid stock outs.

Transportation Optimization

Computer vision can also be used to optimize transportation operations in factories with powerful results.

See how it works

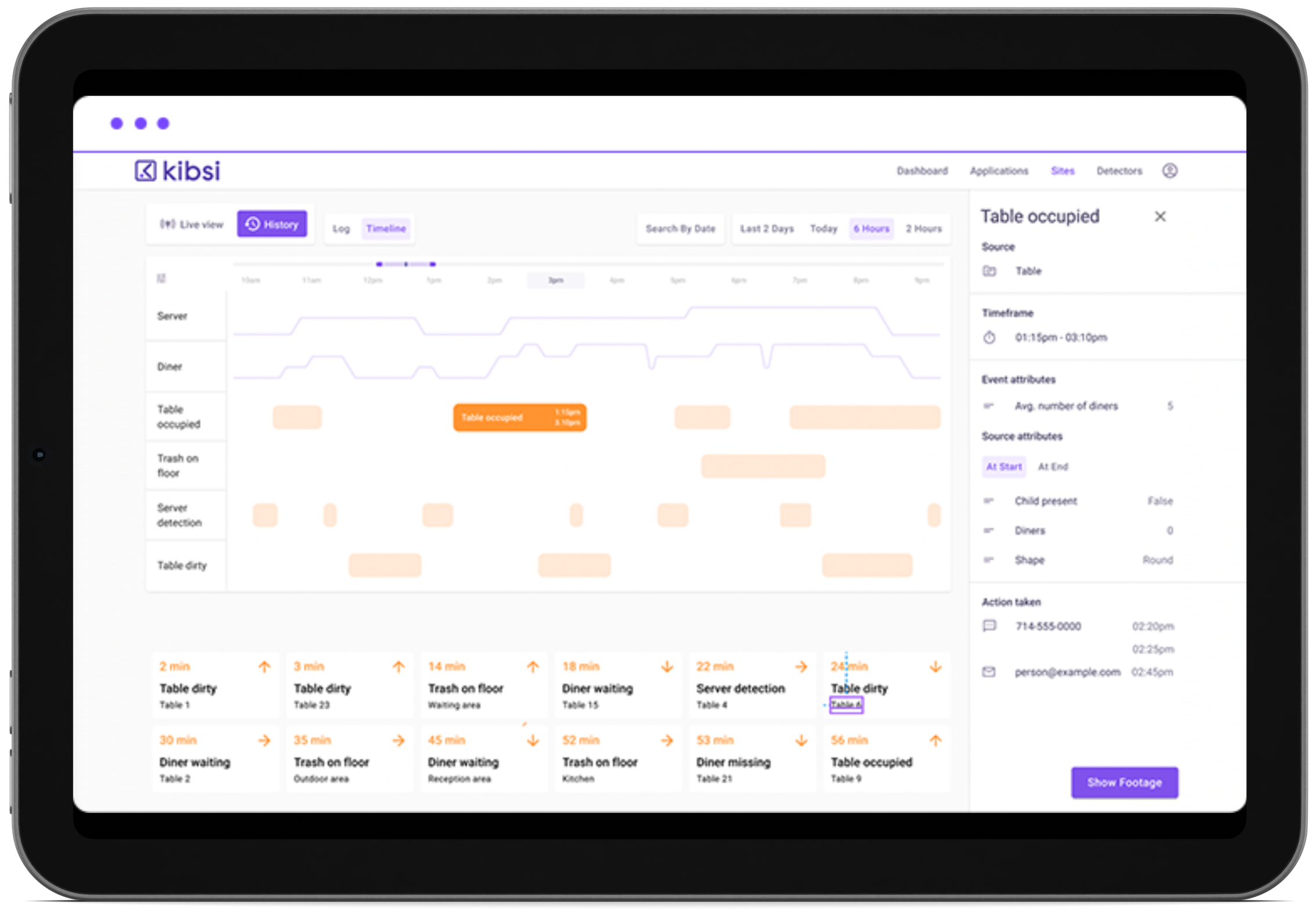

Clearly, there are a lot of ways to use computer vision to improve your factory. However, it can be tough to know where to start or how to implement such a system. That’s where Kibsi comes in.

At Kibsi, we have created the ultimate computer vision platform for businesses. With incredible built- in logic, libraries, and scenarios, it’s easy to point and click your way to a tailored computer vision solution in minutes instead of months. The best part is that most manufacturers can get started simply by connecting to existing security cameras.

We have a team of experts who can help you assess your needs and find the best solution for your factory. Contact us today and learn more about how we can help you leverage computer vision to improve safety, increase efficiency, and deliver better products.

Read our ebook to learn more about them and let us know which would add the most value to your business.

Download our ebook: How Computer Vision is Transforming Manufacturing

Download our ebook: How Computer Vision is Transforming Manufacturing