Introduction

In the rapidly evolving business landscape, the quest for enhanced efficiency and quality has led enterprises, especially those in the industrial sector, to turn to groundbreaking technologies. Computer vision, an embodiment of artificial intelligence and advanced imaging algorithms, has emerged as a critical innovation. It’s not just about machines seeing; it’s about them understanding and interpreting visual data to transform operations.

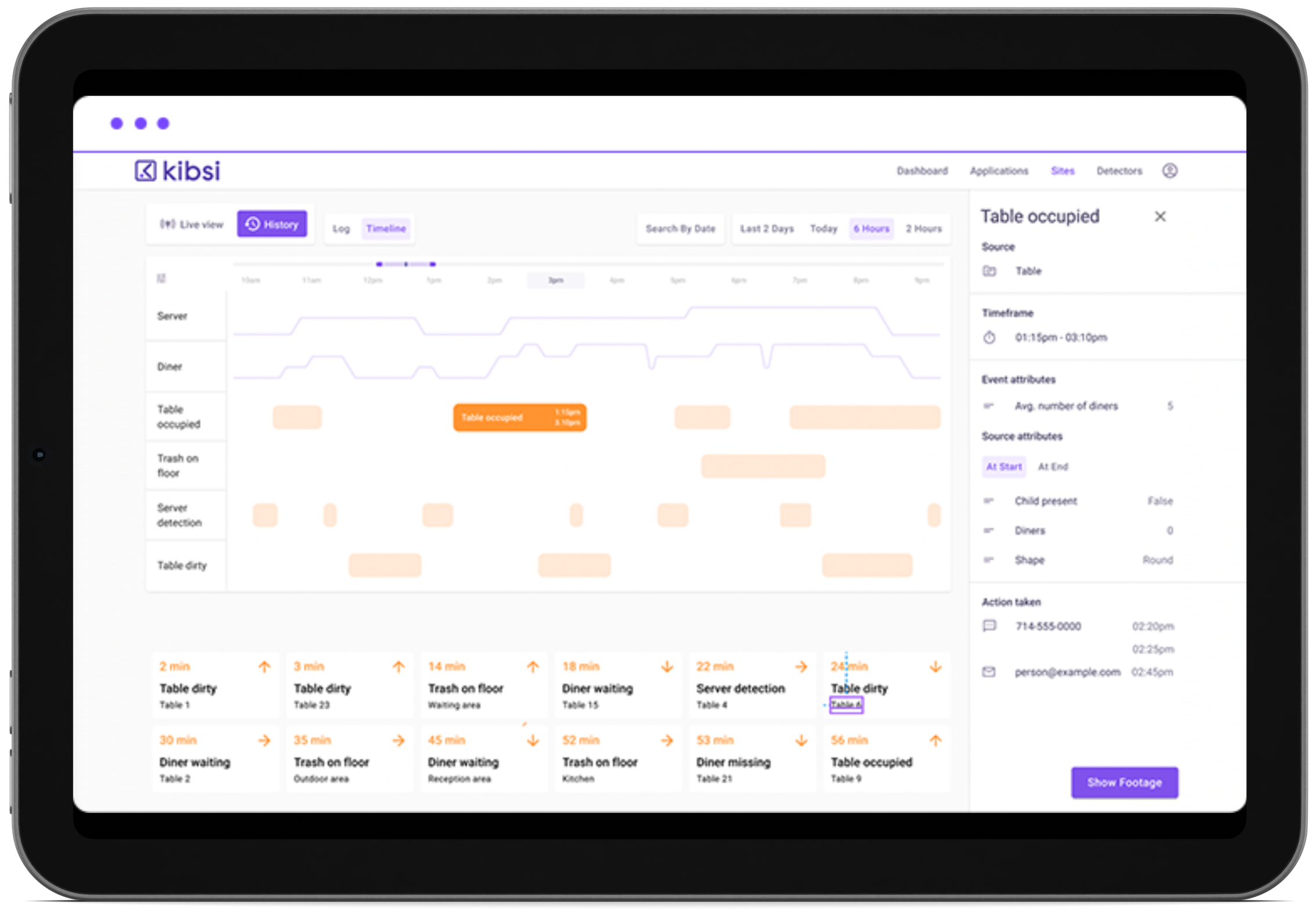

Kibsi offers state-of-the-art computer vision solutions within this technological frontier that reimagine process monitoring. By transcending traditional manual tasks, ensuring compliance, advancing accuracy, and amplifying productivity, Kibsi provides a vision AI platform that reshapes the industrial environment.

The Necessity of Process Monitoring

The backbone of smooth and efficient operations in the industrial domain is robust process monitoring. It’s the linchpin that offers companies the ability to gain real-time insights and swiftly address variances or inefficiencies. Kibsi’s pioneering computer vision technology elevates process monitoring to unprecedented levels.

- Enhanced Quality Assurance

Whether enforcing food safety measures or maintaining meticulous standards on the assembly line, computer vision provides the vigilance necessary to deliver high-caliber outputs while diminishing the potential for defects and non-compliance. - Efficiency Amplified

By identifying production slowdowns and refining workflows, process monitoring facilitated by computer vision paves the path to greater productivity and cost reduction. - Compliance and Safety Ensured

Computer vision monitors equipment usage ensures the right PPE is worn, and monitors vehicle operations. It’s about safeguarding regulatory compliance and preempting accidents or injuries. - Accuracy in Order Fulfillment

As businesses track and verify the precision of shipments and order fulfillment, customer satisfaction climbs, and error margins plummet. - The Path to Continuous Improvement

Analyzing process data through computer vision facilitates identifying enhancement opportunities, enabling organizations to implement data-driven strategies for perpetual operational optimization.

Kibsi’s advanced vision AI platform empowers organizations to harness the full potential of process monitoring, driving efficiency, and securing a competitive edge in the swiftly shifting industrial landscape.

10 Examples of Computer Vision’s Impact on Process Monitoring

Let’s explore some scenarios where computer vision could positively impact process monitoring.

Quality Assurance in Food Safety Procedures

Use Case: Monitoring for Safe Handling and Packaging

Vision AI can be a major asset in the food industry by providing real-time monitoring of food handling and packaging processes. It can ensure all health regulations are met, reducing contamination risks and reinforcing food safety. For instance, Kibsi can track temperatures during processing by “watching” dials and gauges. If there are exceptions, it could generate an alert preventing potential health hazards.

Assembly Line Compliance

Use Case: Ensuring Standard Operating Procedure Adherence

Precision is obviously essential on assembly lines. With a computer vision platform that supports real-time video feed analysis and alert capabilities, any deviation from established procedures is detected immediately, thus preventing potential product defects. Imagine a scenario where a crucial component placement is slightly off on an electronics assembly line—you’re immediately alerted to correct the issue, ensuring product integrity.

Equipment Usage and Safety in Manufacturing

Use Case: Safeguarding Machinery Usage and Employee Proximity

Kibsi’s detection models enhance workplace safety by monitoring the correct use of machinery and the proximity of employees to hazardous areas. Potential safety incidents are pre-empted through these models, and compliance with safety regulations is reinforced. For example, in a facility where heavy or fast-moving machinery operates, Kibsi can alert when an employee gets too close and/or crosses safety lines, preventing potential injuries.

Pallet Loading Accuracy in Warehousing

Use Case: Optimizing Pallet Arrangement and Count

In warehousing, accuracy in pallet loading is essential for storage and transportation efficiency. A quality computer vision platform can confirm the alignment and arrangement of items, optimize the loading process, and ensure inventory accuracy. In the case of logistics operations, Kibsi could verify that each pallet is correctly loaded with the correct number of units before shipment, streamlining the distribution process and avoiding costly order adjustments – not to mention avoiding potential customer satisfaction issues.

Personnel Protective Equipment (PPE) Compliance

Use Case: Automating PPE Usage Detection

Ensuring every employee in designated areas is using the correct PPE is crucial. Kibsi’s automated monitoring facilitates this by detecting PPE usage and reinforcing safety protocols. For example, if an employee enters a construction site without a hard hat, Kibsi’s system can identify the lapse and trigger an alert for immediate action.

Vehicle and Forklift Operations

Use Case: Enhancing Vehicle Operation Safety

Smooth logistics depend on the safe operation of vehicles and forklifts. After all, accidents involving powered industrial vehicles remain one of the most significant potential hazards in the industry. By monitoring traffic patterns and operations, Kibsi could prevent accidents and promote efficient logistics. If a forklift in a warehouse is operating erratically or approaching a pedestrian zone, Kibsi can generate an alert. Through ongoing monitoring and analytics, Kibsi could even highlight a need for additional safety training.

Shipment and Order Fulfillment Accuracy

Use Case: Ensuring Accurate Pick and Pack Processes

Kibsi’s verification systems are crucial in verifying that the correct items and quantities are prepared for customer orders, thus minimizing errors in fulfillment and reducing returns. For example, before a shipment leaves the warehouse, Kibsi can confirm that the order contains the correct products, enhancing customer satisfaction and operational efficiency.

Production Line Bottlenecks

Use Case: Streamlining Workflow by Identifying Slowdowns

Production line bottlenecks can severely impact throughput. Kibsi’s real-time data streams assist in detecting and addressing these blockages, enhancing workflow efficiency. For instance, Kibsi can identify when a machine slows down production due to a maintenance issue, allowing for swift resolution and minimal downtime.

Packaging and Labeling Verification

Use Case: Confirming Accurate Product Packaging

Before products are shipped, they must be correctly packaged and labeled. Kibsi’s technology conducts automated checks to maintain brand reputation and compliance with packaging standards. When packaging labels are incorrect or illegible, Kibsi can spot the error and notify operators to make necessary corrections before products leave for the customer. Plus, thanks to powerful machine learning capabilities, Kibsi can often understand what’s on a label without special programming, making it able to identify things like SKU numbers.

Supply Chain Visibility

Use Case: Tracking Goods for Enhanced Transparency

Not surprisingly, Supply chain visibility is key to managing complex logistics networks. Kibsi’s integration capabilities afford end-to-end visibility and traceability, monitoring goods through each stage of the supply chain. Whether tracking raw materials or finished goods, Kibsi provides the oversight required to maintain a seamless supply chain.

How Kibsi Bolsters ROI Through Process Monitoring

Kibsi’s Vision AI technology is meticulously crafted to yield a robust return on investment in industrial process monitoring. By enabling advanced image analysis, Kibsi helps organizations attain a higher plane of efficiency, precision, and compliance, which translates into substantial savings and productivity gains.

Here’s a breakdown of how Kibsi amplifies ROI in process monitoring:

- Enhanced Quality Control: By pinpointing defects and non-compliances, Kibsi minimizes the chances of substandard products reaching consumers, averting costly recalls and fostering customer trust.

- Surging Productivity: Automating monitoring tasks frees human resources to focus on strategic initiatives, thereby boosting organizational output.

- Streamlined Operations: Kibsi’s real-time intervention allows quick resolution of operational bottlenecks, slashing cycle times and enhancing process fluidity.

- Cost Avoidance: Proactively detecting equipment issues and safety lapses prevent pricey mishaps and legal entanglements.

- Elevated Customer Satisfaction: Kibsi’s commitment to accuracy and timeliness assures a delightful and dependable customer experience, solidifying loyalty and expanding market share.

By leveraging Kibsi’s computer vision platform, organizations can secure measurable ROI, mitigate expenses, and energize customer relations.

Conclusion

The advent of computer vision, propelled by AI, has ushered in a new era in industrial process monitoring. Kibsi stands prominently as a beacon of innovation, delivering tangible returns on investment. By exploiting the capabilities of vision AI, companies can advance quality control, elevate productivity, streamline operations, circumvent costs, and heighten customer contentment.

Kibsi’s powerful computer vision platform and its commitment to real-time performance empower organizations to surge past operational challenges. It guarantees that only the finest products fulfill customer expectations and upholds the sanctity of brand promises.

Ultimately, Kibsi’s computer vision solutions are the natural ally for entities aiming to cement their standing and champion ROI in supply chain, manufacturing, and logistics. Want to see what Kibsi could do for your business? Let’s talk! Book a demo now.