Warehouses are the beating heart of the supply chain, and their efficiency dictates the rhythm of distribution and logistics across industries. With the advent of computer vision technology, a new era of warehouse management is unfolding—one that promises unprecedented levels of precision, speed, and safety. This article, accompanied by a detailed infographic, explores the transformative impact of computer vision on warehouse operations, showcasing the technology’s potential to overhaul traditional practices and set new standards in the industry.

The Rise of Computer Vision in Warehouses

Computer vision, powered by the surge of AI and machine learning, is revolutionizing warehouse operations. Once static repositories of goods, warehouses are now becoming dynamic, intelligent ecosystems. As per Interact Analysis, the warehouse automation market, after a temporary drop, is expected to rebound with a robust 19% compound annual growth rate (CAGR) from 2024 to 2027. This growth is fueled by the continuous expansion of e-commerce and the pressing need for rapid, reliable, and cost-effective distribution systems. The integration of computer vision into warehouses is at the forefront of this growth, serving as a catalyst for innovation and efficiency in logistics.

Key Areas of Transformation

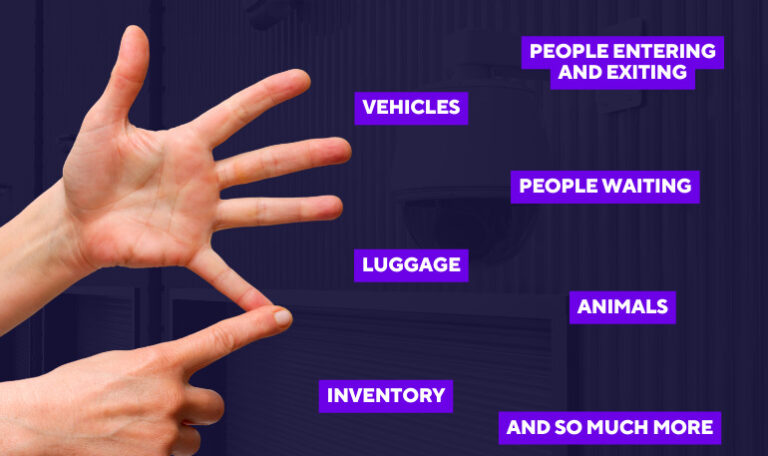

The integration of computer vision in warehouse operations has several key benefits, as illustrated in our infographic. These benefits are substantiated by the predicted growth of the global logistics automation market, which is expected to reach a value of $160.55 billion by 2030. Each point on the infographic represents a pivotal area of enhancement.

7 Ways Computer Vision is Transforming Warehouses

- Overages & Shortages: By enabling precise tracking and identification of goods, computer vision technology minimizes the risks of package loss, theft, or misrouting, ensuring accurate inventory levels.

- Putaway: Computer vision automates the tracking of pallet storage locations, streamlining the putaway process and ensuring optimal space utilization for efficient warehouse operations.

- Shipping Workflow: The technology ensures proper loading counts and accurate pallet identification, key factors in maintaining shipping accuracy and efficiency, thus preventing costly shipping errors.

- Safety: Monitoring the speed, cornering, and proximity of forklifts to objects and people, computer vision enhances workplace safety by proactively identifying potential hazards.

- Receiving Workflow: At the receiving dock, computer vision aids in efficiently managing incoming goods, verifying correct materials and quantities, setting the stage for streamlined warehouse operations.

- Yard Management: Computer vision assists in yard management by tracking and logging truck activities, measuring wait times and activity durations to optimize the flow of goods in and out of the warehouse.

- Container Unloading: By identifying containers and measuring unloading activities, computer vision technology maximizes efficiency, ensuring that goods are accounted for immediately upon unloading and facilitating a smoother transition into the warehouse system.

These areas highlight the beginning of a journey into how computer vision is not just an optional upgrade but a necessity for modern warehouses aiming to stay competitive in a fast-moving industry. In the subsequent sections, we will delve deeper into each area, illustrating the real-world impact of computer vision on the day-to-day operations of warehouses and distribution centers.

Overages & Shortages: Mitigating Inventory Discrepancies

Inventory accuracy is a critical factor in warehouse management, directly impacting customer satisfaction and the bottom line. Computer vision comes into play as a formidable tool in combating overages and shortages. By accurately identifying and counting items, this technology ensures that inventory levels are maintained correctly, preventing the financial losses associated with missing or misrouted packages. The innovative logistics solutions that leverage computer vision can pinpoint the exact location of parts in the warehouse, making real-time inventory management not just a possibility but a reality.

Streamlining Putaway with Automated Tracking

Efficient putaway processes are essential for maximizing storage space and minimizing handling time. Computer vision systems excel in this domain by automatically tracking the storage location of pallets as soon as they are received. This instant capture of data reduces the risk of human error and allows for rapid retrieval, thereby enhancing the overall efficiency of warehouse operations. The ability to track pallets in real-time also aids in optimizing storage density and layout planning, leading to a more organized and productive warehouse environment.

Optimizing the Shipping Workflow

The final step in the warehouse process, shipping, can significantly benefit from computer vision. Ensuring that the right products are loaded onto the right transport vehicles is crucial. Computer vision assists in this process by validating loading counts and identifying pallets with precision. This meticulous level of detail not only prevents shipping errors but also contributes to a seamless supply chain flow. By integrating computer vision into the shipping workflow, warehouses can minimize costly shipping mistakes and improve customer satisfaction through accurate and timely deliveries.

Enhancing Safety in Warehouse Operations

Safety within the warehouse is paramount, and computer vision technology is becoming an indispensable ally in maintaining it. By monitoring the speed, cornering, and proximity of forklifts to both objects and people, computer vision systems can alert managers to potential hazards in real-time. This proactive approach to safety can significantly reduce the risk of accidents, ensuring a safer working environment for all employees. The analytical prowess of computer vision also lends itself to long-term safety improvements by identifying patterns that may contribute to unsafe conditions, thus allowing for preemptive corrective measures.

Receiving Workflow: Boosting Initial Efficiency

The receiving area of a warehouse is where efficiency can be established from the outset. Computer vision systems excel in this initial phase by identifying, tracking, and logging the movements of pallets and containers as they enter the warehouse. This ensures that incoming goods are accounted for accurately and promptly, setting the stage for a streamlined workflow downstream. By automating the inspection of incoming goods, these systems also verify the correct material and quantity upon arrival, which is crucial for maintaining inventory integrity from the very beginning.

Yard Management: The Crucial Link

The yard is a hub of activity that requires meticulous coordination, and computer vision systems offer a level of oversight that manual methods cannot match. By identifying, tracking, and logging the activities of trucks, these systems provide valuable data on wait times and activity durations, critical for optimizing the flow of goods in and out of the warehouse. Effective yard management, facilitated by computer vision, can lead to significant improvements in turnaround times, directly impacting overall warehouse performance and throughput.

Container Unloading: Maximizing Efficiency

Unloading containers is a process where efficiency gains can lead to substantial time and cost savings. Computer vision technology is adept at identifying containers and measuring the activities involved in their unloading. This capability not only speeds up the process but also enhances the accuracy of inventory control as items transition from shipping containers into the warehouse system. Such precise tracking ensures that goods are accounted for from the moment of unloading, reducing the risk of inventory discrepancies and enabling a smoother workflow from the outset.

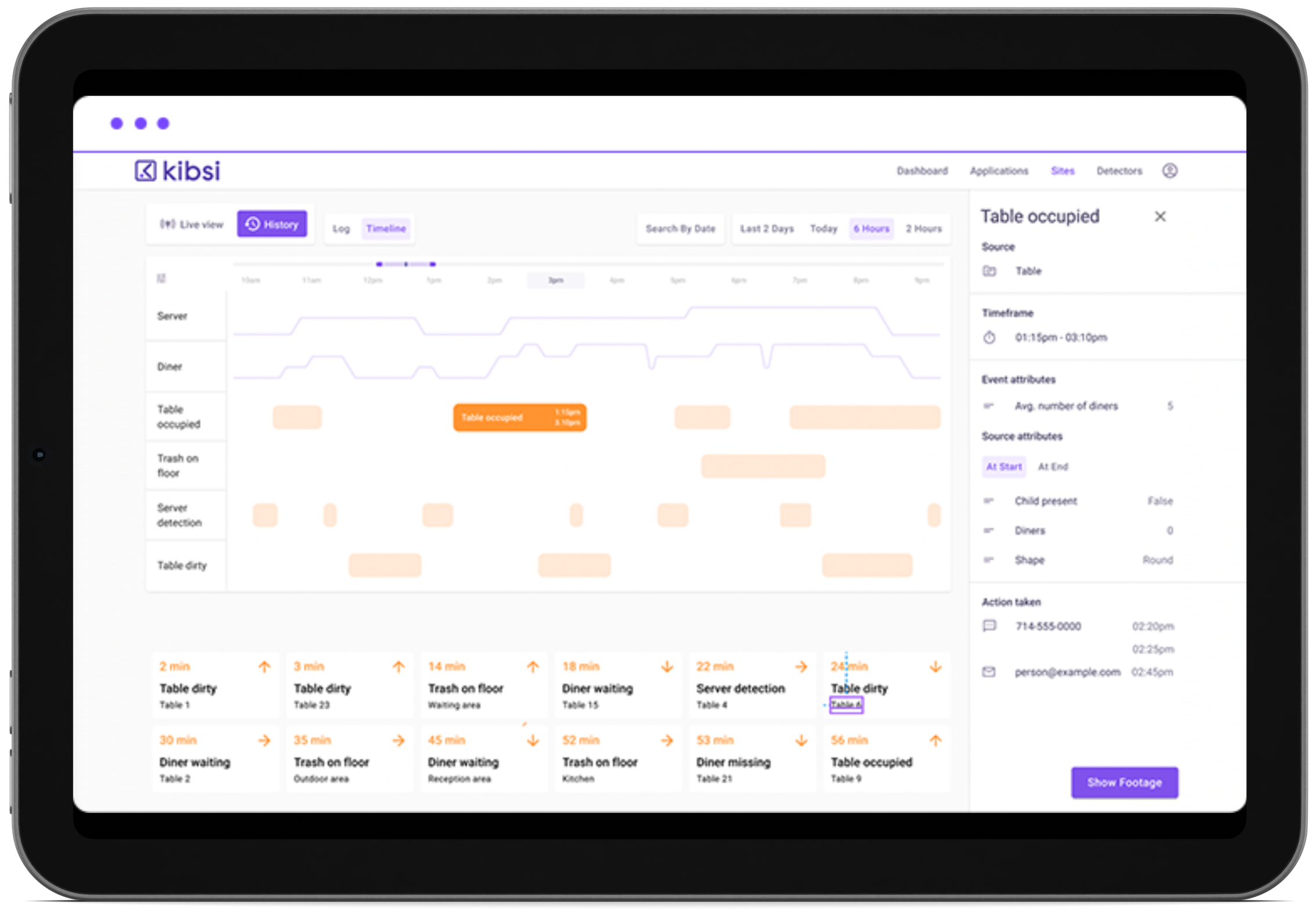

The Future of Warehouse Automation with Kibsi

As warehouses continue to evolve, the role of computer vision as a foundational component of automation becomes increasingly evident. Kibsi’s platform provides the necessary tools and technology to implement these computer vision solutions effectively. With a focus on AI and machine learning, Kibsi transforms complex visual data into actionable insights, leading to more intelligent, responsive, and efficient warehouse operations. As industry leaders like Amazon integrate computer vision to increase efficiency, it’s clear that the future of warehouse automation lies in the adoption of these advanced technologies.

Conclusion

The integration of computer vision into warehouse operations marks a significant advancement in the field of logistics and supply chain management. By enhancing key areas of the warehouse workflow, from safety to unloading efficiency, computer vision technology fosters an environment of continuous improvement. Kibsi stands at the forefront of this technological transformation, offering scalable and adaptable solutions that cater to the diverse needs of modern warehouses. The era of data-driven, AI-enhanced warehousing is here, and it promises to redefine the standards of efficiency, safety, and productivity.

Are you ready to elevate your warehouse operations with the cutting-edge capabilities of computer vision? Kibsi is here to guide you through the transformation. Whether you’re looking to enhance safety protocols, streamline your receiving workflow, or optimize your overall operational efficiency, our platform is designed to make the integration of computer vision technology seamless and straightforward. Book a call to learn more about our solutions and experience firsthand how Kibsi can bring a new level of intelligence to your warehouse operations. Embrace the future of warehousing with Kibsi – where innovation meets practical application.